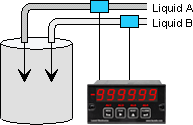

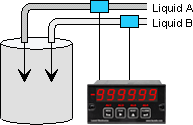

| Controlling the Mixing Ratio of Two Fluids |

|

Displaying and alarming the input flow rate ratio of two fluids (gas or liquid) allows these to be mixed in a predetermined ratio in continuous processes. The sensing element is normally a turbine flowmeter, which outputs pulses at a frequency proportional to flow rate. The A/B ratio can also be displayed for totalized rate (or delivered volume). |

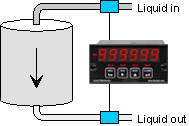

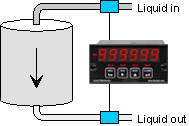

| Computing Net Fluid Inflow & Outflow |

|

The ratio of the inflow and outflow rates of a tank is a measure of the relative filling or emptying rate. The same meter can also be programmed to display the net inflow or outflow rate in flow units, or to display totalized inflow our outflow in volume units. Any of these parameters can be alarmed using the dual relay board and be transmitted via 4-20 mA, RS232 or RS485. |

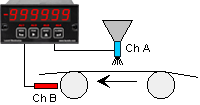

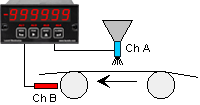

| Controlling Coating Thickness on a Film |

|

In this application, Channel A measures the rate at which a coating material is applied, as measured by a flow meter, while Channel B measures the speed of the film based on pulses from a proximity switch. Displaying and alarming the A/B ratio assures that an even thickness of coating material is applied as the speed of the film is varies. |

| Synchronizing Two Conveyor Lines |

|

The dual-channel Laureate counter can measure the speed of conveyor lines by using the output of proximity switches which sense gear teeth or spokes of rotating drive wheels. Displaying the speed ratio of two lines allows line speeds to be adjusted so that material arrives at work stations when needed. |

| Measuring Draw for Elongation |

|

Draw (Ch A / Ch B - 1) can be used to display the elongation of films compressed between rollers, the shrinkage films, and the RPM difference of rollers whose speed is varied to maintain tension. The six-digit resolution of the Laureate dual channel counter / rate meter is ideal for comparison of rates that are close to each other. |