Features

- Connects a host meter to an Ethernet LAN while also acting as a gatway for up to 31 Laurel devices on an RS485 bus

- Includes an RJ45 jack to the Ethernet LAN plus an RJ11 jack to the RS485 bus

- Suitable for all 1/8 DIN Laureate DPMs, counters, timers & remote displays

- Complemented by Instrument Setup software which discovers Nodes and meters, by Node Manager software, and by built-in web server

- Selectable RS485 baud rates to 9600

- Isolated from meter and power grounds

Certificates of Compliance

The Laureate™ Ethernet-to-RS485 Gateway Board P/N LNET485 plugs into a host 1/8 DIN digital panel meter, counter or timer to provide a 10/100 Base-T Ethernet interface via an industry-standard RJ45 jack for that meter. It also provides an RJ11 jack for interface to an RS485 bus, which can support up to 31 Laurel meters equipped with Laurel's RS485 interface board jumpered for half-duplex operation. That board provides dual RJ11 connectors wired in parallel for RS485 daisy-chaining using commercial 6-wire RJ11 data cables (Laurel cable CBL03), with no need for a hub.

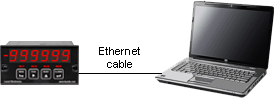

Laurel's free Instrument Setup (IS) software is a Windows-based application which automatically discovers all Laureate Ethernet Nodes on the same Local Area Network (LAN) as the PC, plus any Laureate devices (or meters) associated with that Node. The devices can be the Laureate host meter for the gateway board and any remote Laureate meters on the RS485 bus. Instrument Setup software can be used to program any Laureate instrument, for example to scale the meter reading, scale the analog output, and set relay setpoints. For programming, the PC running Instrument Setup software can be connected to the LNET485 host meter via the LAN or directly to the PC via an Ethernet cable. It can also be connected to each remote RS485 meter via Laurel's cable CBL06. Meters and counters can also be programmed directly from their front panel.

Node Manager software is a free Windows based application which also automatically discovers all Laurel Ethernet Nodes on the same Local Area Network (LAN) as the PC. It adds capabilities such as naming the Node and associated devices, entering email addresses for alarm notification and data requests, selecting the Node's time zone for time-stamping of streaming data, and setting communication parameters for associated meters. It allows emails or text messages to be sent in response to requests from the host computer, periodically, or when devices encounter an alarm condition or go off-line. Node Manager is described in our Ethernet Manual.

On a Wide Area Network (WAN), such as the Internet, the host computer running Instrument Setup software or Node Manager software is outside of the LAN and cannot discover the Nodes on the LAN. The public IP address of the LAN's router must then be entered manually. Web server software built-into each Node can also be used to discover and configure Laurel Nodes over the Internet.

Built-in DHCP server capability allows Laurel Nodes to constitute themselves into a network and be connected directly to a host computer when no router or dedicated DHCP server is present, as illustrated above. When a Node fails to find a DHCP server that responds to its request for a private IP address, it assigns one. When several Nodes fail to receive a Private IP address, they mutually agree to make one of the Nodes a temporary DHCP server that assigns a Private IP address to each device on the network.

Built-in DHCP server capability allows Laurel Nodes to constitute themselves into a network and be connected directly to a host computer when no router or dedicated DHCP server is present, as illustrated above. When a Node fails to find a DHCP server that responds to its request for a private IP address, it assigns one. When several Nodes fail to receive a Private IP address, they mutually agree to make one of the Nodes a temporary DHCP server that assigns a Private IP address to each device on the network.

The Modbus TCP protocol is fully supported. Modbus command cannot only be used to read meters remotely, but also to change setup parameters like setpoints. Conversion to form Modbus RTU to Modbus TCP is transparent so that an Ethernet application can use the Modbus RTU protocol.

Laurel's LNET Ethernet board can be used as an alternative to the server board for networking multiple meters. Each meter will then need to be connected to the network via an Ethernet router, switch or hub, and its own Ethernet cable.

| LNET485 Ethernet Board | |

|---|---|

| Baud rates | 300, 600, 1200, 2400, 4800, 9600 |

| Devices per Ethernet line | 1 host meter for Node plus up to 31 meters on RS485 bus |

| Ethernet connector | RJ45 jack |

| Ethernet cable | 10/100 Base-T |

| Ethernet compliance | IEEE 802.3 |

| Devices per RS485 line | Up to 31 |

| RS485 connector | RJ11 jack |

| RS485 compliance | EIA/TIA-485 |

| Isolation | 250V rms working, 2.3 kV rms per 1 min test |

| ESD Protection | 15 kV per IEC 1000-4-2 |

| EMI Immunity | 10 V/m per IEC 1000-4-3 |

| EFT Protection | 2 kV per IEC 1000-4-4 |

| Short Circuit Protection | Continuous |

| Protocol | Modbus RTU (converted to Modbus TCP). |

| Modbus RTU / TCP | |

| Standards Compliance | Modbus over Serial Line Specification V1.0 (2002) |

| Conversion from RTU to TCP | Automatic |

| Data Formats (selectable) | 1. No parity, 8 data bits, 2 stop bits |

| 2. Odd parity, 8 data bits, 1 stop bit | |

| 3. Even parity, 8 data bits, 1 stop bit | |

| Protocol Type | Master-slave, query-response command mode |

What is an Ethernet-to-RS485 Gateway Board for Laureate Meters, Counters, and Timers?

The Ethernet-to-RS485 Gateway Board is a crucial option board engineered to enhance the connectivity of Laureate Meters, Counters, and Timers, bridging Ethernet and RS485 communication protocols in industrial automation environments. This sophisticated board, featuring an Ethernet port and RS485 interface, facilitates seamless data transfer between IP-based networks and legacy RS485 systems, making it a vital component for integrating these precision instruments into diverse control ecosystems with exceptional interoperability and network scalability.

How Does an Ethernet-to-RS485 Gateway Board Work?

1. Input Signal Integration

The Ethernet-to-RS485 Gateway Board interfaces with Laureate devices, capturing digital signals from their internal processors that reflect real-time measurements from meters, counters, and timers. These signals are prepared for Ethernet-to-RS485 conversion, ensuring compatibility across modern and traditional communication standards.

2. Analog-to-Digital Conversion and Transmission

Utilizing Ethernet protocols (e.g., TCP/IP) and RS485 standards, the board converts measurement data into a dual-format digital stream, translating Ethernet inputs into RS485 outputs with advanced error detection and correction. This process supports bidirectional communication, enabling robust data exchange over extended industrial networks.

3. Display and Data Output

The board transmits real-time data to networked systems like cloud platforms via Ethernet, while simultaneously outputting to RS485 devices, supported by LED indicators for status monitoring. This dual-output capability allows operators to verify connectivity and troubleshoot across both interfaces, enhancing system management and reliability.

4. Additional Connectivity Features

Offering configurable IP addresses, RS485 baud rates (e.g., 9600 to 115200 bps), and data logging options, the Ethernet-to-RS485 Gateway Board adapts to diverse requirements. This flexibility supports advanced applications, including remote diagnostics, integration with hybrid control systems, and extensive performance tracking in complex industrial environments.

Where Are Ethernet-to-RS485 Gateway Boards for Laureate Meters, Counters, and Timers Used?

Ethernet-to-RS485 Gateway Boards are highly versatile components that significantly broaden the operational reach of Laureate Meters, Counters, and Timers across a wide array of industrial and commercial domains. Their ability to bridge Ethernet and RS485 communication makes them essential in settings where precise data monitoring, control, and legacy-modern integration are critical for operational success.

1. Industrial Automation and Control Systems

In industrial automation, these boards enable comprehensive monitoring of production metrics via Laureate devices, integrating Ethernet data with RS485 control panels. In a packaging plant, they synchronize data from counters across legacy conveyor systems, ensuring uniform product output.

2. Power Generation and Distribution

Power facilities use these boards to monitor voltage and current data from Laureate meters, connecting Ethernet to supervisory systems and RS485 to field devices. In a solar power array, they facilitate networked monitoring of panel performance, optimizing energy distribution during peak sunlight hours.

3. Renewable Energy Systems

In solar and wind energy installations, Ethernet-to-RS485 Gateway Boards transmit data from Laureate counters and timers, linking Ethernet to cloud platforms and RS485 to onsite controllers. In a tidal energy project, they monitor turbine cycles, enhancing energy yield under fluctuating tidal conditions.

4. Automotive and Transportation Industry

These boards support voltage monitoring in electric vehicles and trains, connecting Ethernet diagnostics to fleet management and RS485 to onboard systems. In a subway network, they aggregate timer data for schedule adherence, improving passenger safety and operational efficiency.

5. Laboratories and Research Facilities

Research environments rely on these boards for precise data logging from Laureate timers and counters, integrating Ethernet with research networks and RS485 with lab equipment. In a climate research center, they record temperature data, supporting studies on global warming trends.

6. HVAC and Building Automation

In building management, Ethernet-to-RS485 Gateway Boards link Laureate meters to HVAC controls, monitoring temperature and airflow data via Ethernet and RS485. In a smart retail mall, they enable networked climate optimization across stores, reducing energy consumption.

7. Marine and Aerospace Applications

In marine and aerospace, these boards ensure stable voltage monitoring for navigation and life support, connecting Ethernet to mission control and RS485 to onboard systems. On an exploration rover, they monitor electrical loads, ensuring mission success on extraterrestrial surfaces.

Conclusion

The Ethernet-to-RS485 Gateway Board for Laureate Meters, Counters, and Timers stands as a cornerstone of modern industrial connectivity, delivering exceptional precision and interoperability in data communication. Its advanced features, including Ethernet-to-RS485 conversion, multi-device addressing, and real-time monitoring capabilities, empower industries to achieve superior levels of automation, efficiency, and safety. From enhancing production accuracy in manufacturing to optimizing energy output in renewable energy systems, and from ensuring robust diagnostics in transportation to advancing pioneering research in laboratories, this board drives transformative outcomes across diverse sectors. The integration of an Ethernet-to-RS485 gateway not only supports seamless interaction between cutting-edge IP-based systems and established RS485 networks but also opens doors for future innovations in smart industrial ecosystems. As industries increasingly adopt digital transformation, the demand for such dependable and versatile communication solutions will escalate, solidifying the Ethernet-to-RS485 Gateway Board’s status as an indispensable asset. Its ability to connect precise measurement devices with sophisticated control systems enables businesses to secure competitive advantages, reduce operational costs, and elevate product quality, positioning it as a strategic investment for any forward-thinking industrial operation. The ongoing technological evolution, coupled with the board’s proven performance, underscores its enduring relevance and potential to catalyze significant progress in the industrial landscape, extending its impact to emerging fields like retail for point-of-sale system integration, logistics for warehouse automation, and public safety for emergency response coordination for years to come.

Less Information...