Digital Panel Meter for 6-Digit Analog Input Totalizer & Process Applications

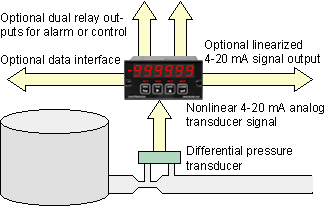

| Flow from a Differential Pressure Transducer | |

|---|---|

|

An ideal application for the Standard Laureate VF meter: readout of flow based on the 4-20 mA analog signal from a differential pressure transducer. Options include dual relays for alarm or control, isolated analog output to turn the meter into a transmitter, and RS232/485 data communications.s |

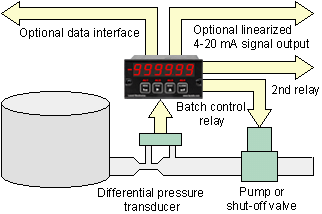

| Up- or Down-Counting Batch Controller | |

|

An ideal application for the Extended Laureate VF meter: up- or down-counting batch controller. The dual-relay card is required. One relay is dedicated to batch control, the other relay is available to alarm the rate or total. The signal input can be linear or nonlinear. The display can be toggled between rate and total. |

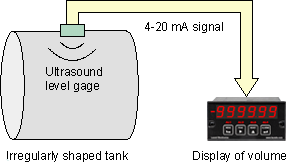

| Volume of an Irregularly-Shaped Tank | |

|

The Extended Laureate VF meter can linearize analog signals for display and alarm using custom curve linearization with multiple nonlinear segments. As illustrated, tank level is measured by an ultrasound detector, which transmits a 4-20 mA signal. This signal is then converted to a highly accurate volume reading. Linearized readings can also be totalized. |

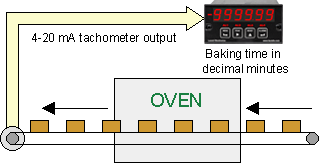

| Process Time from an Analog Rate Signal | |

|

A unique application of the Extended Laureate VF meter is displaying process time based on the 4-20 mA or 0-10 V signal from a rate meter. In this example, a tachometer transmits the speed of a conveyer belt through an oven. The meter displays baking time in the oven using the mathematical relationship time = distance / speed. |

Sample Applications for 6-Digit Analog Input Totalizer and Process Applications Using the 1/8 DIN Digital Panel Meter

Introduction

In industrial automation, manufacturing, and process control, accurate measurement and totalization of analog signals are critical for tracking quantities like flow, energy, or material usage. Digital Panel Meters, such as the 1/8 DIN Digital Panel Meter for 6-Digit Analog Input Totalizer and Process Meter from Laurel Electronics’ Laureate series, are designed to process analog signals (e.g., 4-20 mA, 0-10 V) from transducers, delivering precise rate and total measurements. Featuring a 6-digit LED display, ±0.02% accuracy, and robust connectivity, this Digital Panel Meter is ideal for totalizer and process applications. This section explores where and how Digital Panel Meters are used in these applications, along with specific use cases, highlighting their essential role in industrial settings.

Understanding DIN Standards

The term "DIN" refers to the Deutsches Institut für Normung, the German Institute for Standardization, which establishes global standards for industrial components. The "1/8 DIN" designation indicates a compact size, with the Digital Panel Meter’s front panel measuring approximately 48 x 96 mm (1.89 x 3.78 inches). This space-efficient design makes Digital Panel Meters ideal for integration into control panels, particularly in environments with limited space.

What is a 1/8 DIN Digital Panel Meter for 6-Digit Analog Input Totalizer and Process Applications?

The 1/8 DIN Digital Panel Meter for 6-Digit Analog Input Totalizer and Process Applications is a high-precision device optimized for processing analog signals (0-1 mA, 4-20 mA, 0-10 V) from transducers like flow meters or pressure sensors, delivering rate and cumulative total measurements. It supports input ranges from ±200 mV to ±600 V or ±2 mA to ±5 A, with a 6-digit display offering resolutions up to ±999,999 counts. Equipped with features like programmable scaling, setpoint control, and serial communication (RS-232, RS-485, Modbus), this Digital Panel Meter is a key tool for monitoring and controlling process variables in industrial automation.

How Is It Used?

Digital Panel Meters process analog signals to deliver accurate rate and totalized data, integrating seamlessly into control systems. The operational process includes:

-

Signal Acquisition: Captures analog signals (e.g., 4-20 mA, 0-10 V) from transducers like flow meters or pressure sensors, with jumper-selectable input ranges.

-

Signal Processing: Employs Concurrent Slope analog-to-digital conversion with a 60 Hz update rate to transform signals into rate or total values, using digital filtering to eliminate noise and ensure stability.

-

Display: Shows measurements on a 6-digit LED display, scalable to engineering units (e.g., gallons, kWh) from -999,999 to +999,999, with ±0.02% accuracy.

-

Output and Control: Provides dual 8A relays for setpoint control (e.g., batch completion alarms), a 4-20 mA or 0-10 V analog output, and serial communication (RS-232, RS-485, Modbus) for integration with PLCs or SCADA systems.

-

Excitation Supply: Delivers isolated 5 V, 10 V, or 24 V excitation to power transducers, ensuring stable operation without external power sources.

Where Is a 1/8 DIN Digital Panel Meter for 6-Digit Analog Input Totalizer and Process Applications Used?

Digital Panel Meters are deployed in environments requiring precise measurement and totalization of analog signals, spanning industrial, manufacturing, and processing settings. Their compact size and high accuracy make them ideal for:

-

Industrial Process Control: Used in manufacturing plants to monitor flow rates, totals, or other process variables, ensuring efficiency with Digital Panel Meters.

-

Water Treatment: Tracks cumulative flow volumes or chemical dosing for regulatory compliance, with Digital Panel Meters enhancing accuracy.

-

Energy Management: Monitors energy consumption or production totals, supported by Digital Panel Meters’ reliable performance.

-

Food and Beverage Industry: Totalizes ingredient quantities or monitors process variables, with Digital Panel Meters ensuring consistency.

-

Laboratory Research: Measures and totals experimental data, supported by Digital Panel Meters’ high-resolution displays.

Applications for Analog Input Totalizer and Process Use Cases

- Industrial Automation

- Flow Totalization: Digital Panel Meters accumulate flow totals from 4-20 mA flow meters, tracking cumulative volumes like gallons or liters in manufacturing processes.

- Process Rate Monitoring: Digital Panel Meters measure flow or production rates, ensuring processes stay within specified limits for quality control.

- Water Treatment

- Water Volume Tracking: Digital Panel Meters totalize water flow from treatment systems, ensuring compliance with regulatory standards.

- Chemical Dosing Monitoring: Digital Panel Meters track cumulative chemical usage from dosing pumps, maintaining precise water treatment processes.

- Energy Management

- Energy Consumption Totalization: Digital Panel Meters accumulate energy usage from 4-20 mA watt meters, supporting cost allocation and efficiency analysis.

- Renewable Energy Monitoring: Digital Panel Meters totalize energy output from solar or wind systems, ensuring accurate tracking.

- Food and Beverage Processing

- Ingredient Totalization: Digital Panel Meters measure cumulative quantities of ingredients, like liquids or powders, for consistent batch production.

- Packaging Monitoring: Digital Panel Meters track total weights or volumes in packaging lines, ensuring compliance with standards.

- Laboratory Research

- Experimental Data Totalization: Digital Panel Meters accumulate data from transducers in experiments, ensuring accurate measurements for research outcomes.

- Sensor Calibration: Digital Panel Meters verify transducer performance in calibration setups, supporting precise data collection.

Why Choose a 1/8 DIN Digital Panel Meter for 6-Digit Analog Input Totalizer and Process Applications?

Digital Panel Meters, such as the Laureate 1/8 DIN model, offer exceptional precision, robust connectivity, and a compact design, making them ideal for analog input totalizer and process applications. Their ability to process a wide range of analog signals, perform accurate totalization, and support features like setpoint control and serial communication ensures reliable performance. Digital Panel Meters integrate seamlessly into modern automation systems, enhancing efficiency, accuracy, and control.

Conclusion

The 1/8 DIN Digital Panel Meter for 6-Digit Analog Input Totalizer and Process Applications is a powerful and versatile tool for industrial automation, water treatment, energy management, food processing, and laboratory research. Its high-precision 6-digit display, ±0.02% accuracy, and advanced features like programmable scaling and Modbus connectivity ensure reliable measurement of rates and totals. Operating from -40°C to 70°C with CE/RoHS3 compliance, Digital Panel Meters are a cornerstone of modern process monitoring and control systems, supporting accuracy and efficiency across diverse industries.

Less Information.