Digital Panel Meter for Dual-Channel Pulse Input Totalizer Applications

| Up/Down Totalizing | |

|---|---|

|

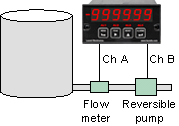

Up/down totalizing is provided by a mode of the Extended counter where pulses are either added or subtracted on Channel A based on a direction input on Channel B. The counter can also be programmed so that counting by Channel A is inhibited by an input on Channel B. |

| Combining Two Totals | |

|

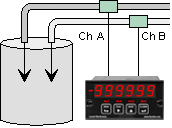

A+B, A-B and A/B arithmetic functions are available with the Extended counter. A+B sums both totals, while A-B subtracts the outflow total from inflow total. The A/B ratio applied to total helps assure the proper mixing of components. Controller setup and monitoring of the mixing operation are facilitated by optional serial communications. RS485 allows a single data line to handle multiple controllers. |

| Up or Down Counting with Preset | |

|

A single Laureate dual-channel counter will handle two repetitive fill operations by counting from zero up to a preset, or down from a preset to zero. A dual setpoint relay board is required. |

| Machine Rune Time and Utilization | |

|

An easy way to measure the run time of machines is to count AC line cycles and scale the total to hours. To display machine utilization or duty cycle in percent, use the Extended counter. Connect Channel A to switched AC and Channel B to the AC line, and have the counter display the A/B ratio with a 100 multiplier. |

| Total and Rate Simultaneously | |

|

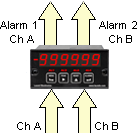

The Extended version of the Laureate dual channel counter can display scaled rate or total for the same channel at the push of a button, and alarm both the rate and total. The Extended version can also do curve linearization, thereby extending the working range and accuracy of flow transducers. |

| System-level Capabilities | |

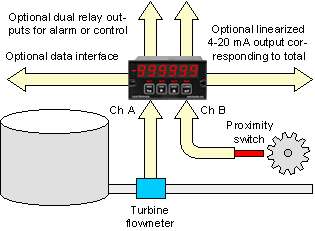

| The Laureate dual channel totalizer can independently scale, display and alarm two totals, and the totals plus alarm data can be transmitted via RS232 or RS485. The displayed totals can also be transmitted as an isolated 4-20 mA or 0-10V analog output. The Extended version can further display and transmit arithmetic combinations of the two totals. |  |

Sample Applications for Dual-Channel Pulse Input Totalizer Applications Using the 1/8 DIN Digital Panel Meter

Introduction

In industrial automation, manufacturing, and process control, accurate counting and totalization of pulse signals are essential for tracking quantities like flow, production counts, or energy usage. Digital Panel Meters, such as the 1/8 DIN Digital Panel Meter for Dual-Channel Pulse Input Totalizer from Laurel Electronics’ Laureate series, are designed to process pulse signals from two independent channels, delivering precise cumulative totals. Featuring a 6-digit LED display, ±0.005% accuracy, and robust connectivity, this Digital Panel Meter is ideal for dual-channel totalizer applications. This section explores where and how Digital Panel Meters are used in dual-channel pulse input totalizer applications, along with specific use cases, highlighting their critical role in industrial settings.

Understanding DIN Standards

The term "DIN" refers to the Deutsches Institut für Normung, the German Institute for Standardization, which establishes global standards for industrial components. The "1/8 DIN" designation indicates a compact size, with the Digital Panel Meter’s front panel measuring approximately 48 x 96 mm (1.89 x 3.78 inches). This space-efficient design makes Digital Panel Meters ideal for integration into control panels, particularly in environments with limited space.

What is a 1/8 DIN Digital Panel Meter for Dual-Channel Pulse Input Totalizer Applications?

The 1/8 DIN Digital Panel Meter for Dual-Channel Pulse Input Totalizer is a high-precision device optimized for counting and totalizing pulse signals from two independent sources, such as flow meters, tachometers, or proximity switches. It supports input frequencies from 0.005 Hz to 1 MHz and offers a 6-digit display with resolutions up to ±999,999 counts. Equipped with features like programmable scaling, setpoint control, and serial communication (RS-232, RS-485, Modbus), this Digital Panel Meter is a key tool for monitoring cumulative quantities in industrial automation.

How Is It Used?

Digital Panel Meters process dual-channel pulse signals to deliver accurate totalized counts, integrating seamlessly into control systems. The operational process includes:

-

Signal Acquisition: Captures pulse signals from two channels (A and B) via sensors like NPN/PNP proximity switches, contact closures, or AC signals (12 mV to 250 V AC), with jumper-selectable input ranges.

-

Signal Processing: Employs a high-speed counter with a quartz crystal time base to count pulses, calculating totals with ±0.005% accuracy and a 60 Hz update rate, with digital filtering to reduce noise.

-

Display: Shows cumulative totals on a 6-digit LED display, scalable to engineering units (e.g., liters, units) from -999,999 to +999,999, with customizable formats.

-

Output and Control: Provides dual 8A relays for setpoint control (e.g., batch completion alarms), a 4-20 mA or 0-10 V analog output, and serial communication (RS-232, RS-485, Modbus) for integration with PLCs or SCADA systems.

-

Signal Conditioning: Supports programmable gate times and digital filtering to ensure stable and accurate totalization, with options for arithmetic operations like A+B or A-B on dual channels.

Where Is a 1/8 DIN Digital Panel Meter for Dual-Channel Pulse Input Totalizer Applications Used?

Digital Panel Meters are deployed in environments requiring precise totalization of pulse signals from two sources, spanning industrial, manufacturing, and processing settings. Their compact size and high accuracy make them ideal for:

-

Industrial Process Control: Used in manufacturing plants to totalize quantities like flow or production counts, ensuring efficiency with Digital Panel Meters.

-

Water Treatment: Tracks cumulative flow volumes for regulatory compliance, supported by Digital Panel Meters’ reliable performance.

-

Energy Management: Monitors energy usage from dual pulse-output meters, with Digital Panel Meters enhancing accuracy.

-

Manufacturing Automation: Counts production outputs or material quantities, supported by Digital Panel Meters’ dual-channel capabilities.

-

Material Handling: Tracks items or volumes in conveyor systems, with Digital Panel Meters providing precise totalization.

Applications for Dual-Channel Pulse Input Totalizer Use Cases

- Industrial Automation

- Flow Totalization: Digital Panel Meters accumulate flow totals from two flow meters (e.g., liters from dual pipelines), using A+B to calculate combined volume or A-B to determine net flow.

- Batch Counting: Digital Panel Meters track batch quantities from two production lines, ensuring accurate inventory and quality control.

- Water Treatment

- Water Volume Tracking: Digital Panel Meters totalize water flow from dual channels in treatment plants, ensuring compliance with regulatory standards.

- Chemical Dosing Monitoring: Digital Panel Meters count pulses from dosing pumps to track cumulative chemical usage.

- Energy Management

- Power Consumption Totalization: Digital Panel Meters accumulate energy usage from two kWh meters, supporting cost allocation and efficiency analysis.

- Renewable Energy Monitoring: Digital Panel Meters track energy output from dual solar or wind sources, ensuring accurate totalization.

- Manufacturing Automation

- Production Counting: Digital Panel Meters count items produced on two assembly lines, using A+B for total output or A-B for defect subtraction.

- Machine Cycle Tracking: Digital Panel Meters monitor cycle counts from dual machines, ensuring performance optimization.

- Material Handling

- Conveyor Counting: Digital Panel Meters totalize items or packages on dual conveyor lines, ensuring accurate tracking for logistics.

- Inventory Management: Digital Panel Meters count material quantities from two sources, supporting precise stock control.

Why Choose a 1/8 DIN Digital Panel Meter for Dual-Channel Pulse Input Totalizer Applications?

Digital Panel Meters, such as the Laureate 1/8 DIN model, offer exceptional precision, robust connectivity, and a compact design, making them ideal for dual-channel pulse input totalizer applications. Their ability to process signals from two independent sources, perform arithmetic operations, and support features like setpoint control and serial communication ensures reliable performance. Digital Panel Meters integrate seamlessly into modern automation systems, enhancing efficiency, accuracy, and control.

Conclusion

The 1/8 DIN Digital Panel Meter for Dual-Channel Pulse Input Totalizer Applications is a powerful and versatile tool for industrial automation, water treatment, energy management, manufacturing, and material handling. Its high-precision 6-digit display, ±0.005% accuracy, and advanced features like dual-channel processing and Modbus connectivity ensure reliable totalization of pulse signals. Operating from -40°C to 70°C with CE/RoHS3 compliance, Digital Panel Meters are a cornerstone of modern counting and monitoring systems, supporting accuracy and efficiency across diverse industries.

Less Information.