Digital Panel Meter for Load Cell, Strain Gauge, and Microvolt Applications

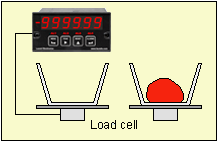

To read the net weight of an object, the empty container is first weighed, and an external button is pushed to zero out the display. The meter will then read net weight when an object is added to the empty container. The tare value is stored in memory for subsequent readings.

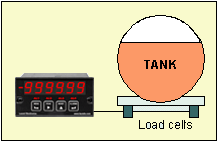

An easy way to determine volume of an irregularly shaped tank with no need for linearizing is to weigh the tank using load cells. The meter will automatically tare out the weight of the empty tank and then scale the load cell signals to units of volume, such as liters or gallons.

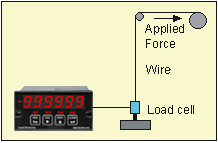

Peak readings are automatically captured at rates up to 60 per second, while the display updates at a legible 3.5 per second. The peak reading can be recalled at the push of a button or be always displayed. It can also be transmitted to a computer via RS232, RS485, USB or Ethernet.

Sample Applications for Load Cell Applications Using the 1/8 DIN Digital Panel Meter

Introduction

In industrial automation and precision measurement, load cells are essential for accurate weight and force monitoring. Digital Panel Meters, such as the 1/8 DIN Digital Panel Meter for Load Cell, Strain Gauge, and Microvolt Signals from Laurel Electronics’ Laureate series, provide a high-precision solution for interfacing with load cells. This Digital Panel Meter delivers reliable weight measurements for various applications, featuring a 6-digit LED display, ±0.01% accuracy, and robust connectivity. This section explores where and how Digital Panel Meters are used in load cell applications, along with specific use cases, highlighting their critical role in industrial and laboratory environments.

Understanding DIN Standards

The term "DIN" refers to the Deutsches Institut für Normung, the German Institute for Standardization, which establishes global standards for industrial components. The "1/8 DIN" designation indicates a compact size, with the Digital Panel Meter’s front panel measuring approximately 48 x 96 mm (1.89 x 3.78 inches). This space-efficient design makes Digital Panel Meters ideal for integration into control panels, particularly in environments with limited space.

What is a 1/8 DIN Digital Panel Meter for Load Cell Applications?

The 1/8 DIN Digital Panel Meter for Load Cell, Strain Gauge, and Microvolt Signals is a specialized device optimized for processing low-level signals from load cells and strain gauges. With a 6-digit display, it offers high-precision weight or force measurements, supporting 4- or 6-wire load cell configurations and input sensitivities from 20 mV to 500 mV full scale. Equipped with features like auto-tare, setpoint control, and serial communication (RS-232, RS-485, Modbus), this Digital Panel Meter is a cornerstone for load cell-based weighing systems in industrial automation.

How Is It Used?

Digital Panel Meters process microvolt signals from load cells to deliver accurate weight or force data, integrating seamlessly into control systems. The operational process includes:

-

Signal Acquisition: Receives microvolt signals from load cells or strain gauges via 4- or 6-wire connections, with 6-wire setups compensating for lead resistance to enhance accuracy.

-

Signal Processing: Employs a high-speed analog-to-digital converter (ADC) with a 60 Hz update rate to convert signals into weight or force values, using digital filtering to eliminate noise.

-

Display: Shows weight data on a 6-digit LED display, customizable for units like kg, lb, or N, with ±0.01% accuracy and resolutions up to 1:60,000.

-

Output and Control: Provides dual 8A relays for setpoint control, a 4-20 mA analog output, and serial communication (RS-232, RS-485, Modbus) for integration with PLCs or SCADA systems.

-

Excitation Supply: Supplies an isolated 10 V, 120 mA excitation to power up to four 350-ohm load cells, ensuring stable operation without external power sources.

Where Is a 1/8 DIN Digital Panel Meter for Load Cell Applications Used?

Digital Panel Meters are deployed in environments requiring precise weight or force measurement using load cells, spanning industrial, commercial, and laboratory settings. Their compact size and high accuracy make them ideal for:

-

Industrial Weighing Systems: Used in manufacturing plants to monitor material weights, ensuring accurate batching and quality control with Digital Panel Meters.

-

Process Control: Integrated into automated systems to measure forces in material handling or production processes, leveraging the precision of Digital Panel Meters.

-

Laboratory Testing: Employed in research labs for precise force or weight measurements in experiments, supported by Digital Panel Meters’ high-resolution displays.

-

Food and Beverage Industry: Utilized for weighing ingredients or packaged products to ensure compliance and consistency, with Digital Panel Meters enhancing accuracy.

-

Logistics and Warehousing: Monitors load weights in shipping and inventory management systems, facilitated by Digital Panel Meters’ reliable performance.

Applications for Load Cell Use Cases

- Industrial Automation

- Batch Weighing: Digital Panel Meters control the precise dispensing of materials, such as chemicals or raw materials, in manufacturing by measuring load cell outputs and triggering setpoints for filling operations.

- Force Monitoring: Digital Panel Meters measure forces in automated machinery, such as press or stamping systems, to ensure consistent performance and prevent overload.

- Food and Beverage Processing

- Ingredient Weighing: Digital Panel Meters ensure accurate measurement of ingredients, like flour or liquids, in food production for consistent batch quality.

- Packaging: Digital Panel Meters monitor the weight of packaged goods, such as bottles or containers, to meet regulatory standards and ensure customer satisfaction.

- Laboratory and Research

- Material Testing: Digital Panel Meters measure forces in tensile or compression tests using strain gauges, providing precise data for material strength analysis.

- Experimental Weighing: Digital Panel Meters track sample weights in scientific experiments, ensuring accurate data for research outcomes.

- Logistics and Transportation

- Truck Scales: Digital Panel Meters monitor vehicle or cargo weights to ensure compliance with legal load limits and optimize transport efficiency.

- Warehouse Inventory: Digital Panel Meters track inventory weights for accurate stock management and order fulfillment.

- Energy and Utilities

- Tank Weighing: Digital Panel Meters measure the weight of materials in storage tanks, such as fuel or chemicals, for inventory and process control.

- Structural Monitoring: Digital Panel Meters use strain gauges to monitor forces in infrastructure, ensuring safety and stability.

Why Choose a 1/8 DIN Digital Panel Meter for Load Cell Applications?

Digital Panel Meters, such as the Laureate 1/8 DIN model, offer unmatched precision, robust connectivity, and a compact design, making them ideal for load cell applications. Their ability to handle microvolt signals, provide stable excitation, and support advanced control features ensures accurate and reliable measurements. With options for auto-tare, setpoint control, and serial communication, Digital Panel Meters integrate seamlessly into modern automation systems, enhancing efficiency and safety.

Conclusion

The 1/8 DIN Digital Panel Meter for Load Cell, Strain Gauge, and Microvolt Signals is a powerful and versatile tool for load cell applications in industrial automation, food processing, laboratory research, logistics, and energy management. Its high-precision 6-digit display, ±0.01% accuracy, and robust features ensure reliable weight and force measurements, supporting quality, efficiency, and compliance across diverse use cases. Operating from -40°C to 70°C with CE/RoHS3 compliance, Digital Panel Meters are a cornerstone of modern weighing and force measurement systems.

Less Information.