Digital Panel Meter for Quadrature Encoder Input for Bidirectional Position or Rate Applications

| Using Quadrature for Cutting to Length | |

|---|---|

|

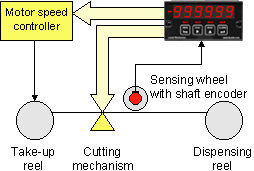

Controlling the repetitive cutting of material to length is an excellent application of the Laureate quadrature meter. The quadrature encoder shares the shaft of a sensing wheel, whose rotation corresponds to lineal displacement of material. The meter compares the displacement reading against setpoint information, and then uses its dual relays to first slow down and then cut the material. |

| Using Quadrature for X-Y Positioning | |

|

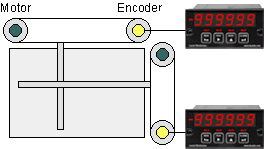

Accurate X-Y position or rate can be obtained from two shaft encoders, which convert linear position to quadrature signals as a shaft turns. In addition to serving as a display, each Laureate can use its optional dual relay setpoint capability for closed loop control. It can also transmit data via RS232, RS485, or a 4-20 mA analog signal. |

| Using Quadrature to Monitor a Drilling Operation | |

|

Quadrature can be used to track position and vertical drilling speed of the bit in an oil drilling operation. A shaft encoder is rotated by a cable that moves with the drilling shaft. In this application, the same encoder signal is applied to a Laureate quadrature meter for position, and to a second quadrature meter for rate. Both meters can be scaled to read out in appropriate engineering units, such as feet and inches per minute, and can be alarmed. A Laureate 6-digit remote display could be added to read out peak rate. |

Sample Applications for Quadrature Encoder Input Applications Using the 1/8 DIN Digital Panel Meter

Introduction

In industrial automation, manufacturing, and motion control, precise measurement of bidirectional position or rate is critical for ensuring process accuracy and system reliability. Digital Panel Meters, such as the 1/8 DIN Digital Panel Meter for Quadrature Encoder Input and Bidirectional Position or Rate from Laurel Electronics’ Laureate series, are designed to process quadrature signals from encoders, delivering accurate position and speed measurements. Featuring a 6-digit LED display, ±0.005% accuracy, and robust connectivity, this Digital Panel Meter is ideal for quadrature encoder applications. This section explores where and how Digital Panel Meters are used in quadrature encoder input applications, along with specific use cases, highlighting their essential role in industrial settings.

Understanding DIN Standards

The term "DIN" refers to the Deutsches Institut für Normung, the German Institute for Standardization, which establishes global standards for industrial components. The "1/8 DIN" designation indicates a compact size, with the Digital Panel Meter’s front panel measuring approximately 48 x 96 mm (1.89 x 3.78 inches). This space-efficient design makes Digital Panel Meters ideal for integration into control panels, particularly in environments with limited space.

What is a 1/8 DIN Digital Panel Meter for Quadrature Encoder Input Applications?

The 1/8 DIN Digital Panel Meter for Quadrature Encoder Input and Bidirectional Position or Rate is a high-precision device optimized for processing quadrature signals (A and B channels, 90° out of phase) from encoders, measuring bidirectional position (e.g., distance, angle) or rate (e.g., speed, RPM). It supports input frequencies from 0 Hz to 1 MHz and offers a 6-digit display with resolutions up to ±999,999 counts. Equipped with features like programmable scaling, setpoint control, and serial communication (RS-232, RS-485, Modbus), this Digital Panel Meter is a key tool for motion control in industrial automation.

How Is It Used?

Digital Panel Meters process quadrature signals to deliver accurate position or rate data, integrating seamlessly into control systems. The operational process includes:

-

Signal Acquisition: Captures A and B channel pulse signals from quadrature encoders, such as those on rotary or linear encoders, with jumper-selectable inputs (12 mV to 250 V AC).

-

Signal Processing: Employs a high-speed counter with a quartz crystal time base to decode phase relationships, calculating bidirectional position or rate with ±0.005% accuracy and a 60 Hz update rate.

-

Display: Shows measurements on a 6-digit LED display, scalable to engineering units (e.g., mm, RPM) from -999,999 to +999,999, with customizable formats.

-

Output and Control: Provides dual 8A relays for setpoint control (e.g., position or speed alarms), a 4-20 mA or 0-10 V analog output, and serial communication (RS-232, RS-485, Modbus) for integration with PLCs or SCADA systems.

-

Signal Conditioning: Supports digital filtering to reduce noise and programmable scaling to align with specific encoder resolutions, ensuring precise measurements.

Where Is a 1/8 DIN Digital Panel Meter for Quadrature Encoder Input Applications Used?

Digital Panel Meters are deployed in environments requiring precise measurement of bidirectional position or rate, spanning industrial, manufacturing, and automation settings. Their compact size and high accuracy make them ideal for:

-

Industrial Automation: Used in manufacturing plants to monitor position or speed in motion control systems, ensuring precision with Digital Panel Meters.

-

Robotics: Tracks movements in robotic systems, with Digital Panel Meters enhancing accuracy.

-

Manufacturing Automation: Measures position or rate in production lines, supported by Digital Panel Meters’ reliable performance.

-

Renewable Energy: Monitors component positions or speeds in energy systems, with Digital Panel Meters providing robust capabilities.

-

Laboratory Testing: Measures position or rate in research setups, supported by Digital Panel Meters’ high-resolution displays.

Applications for Quadrature Encoder Input Use Cases

- Industrial Automation

- Machine Positioning: Digital Panel Meters track the position of machine components (e.g., CNC tools) using quadrature encoders, ensuring precise machining operations.

- Speed Monitoring: Digital Panel Meters measure conveyor or motor speeds in RPM, triggering alarms for deviations to maintain efficiency.

- Robotics

- Arm Positioning: Digital Panel Meters monitor the position of robotic arms, ensuring accurate and repeatable movements for assembly tasks.

- Motion Control: Digital Panel Meters track rotational speeds of robotic joints, supporting precise control in automated systems.

- Manufacturing Automation

- Conveyor Positioning: Digital Panel Meters measure the position of items on conveyor lines, ensuring accurate sorting or placement.

- Production Rate Tracking: Digital Panel Meters monitor production line speeds, optimizing throughput and quality control.

- Renewable Energy

- Solar Tracker Positioning: Digital Panel Meters track solar panel positions to optimize sun exposure, using quadrature encoders for precise alignment.

- Wind Turbine Speed Monitoring: Digital Panel Meters measure blade rotation speeds, ensuring efficient energy generation.

- Laboratory Testing

- Motion Analysis: Digital Panel Meters measure position or rate in experimental setups, ensuring accurate data for research outcomes.

- Encoder Calibration: Digital Panel Meters verify encoder performance in calibration setups, supporting precise motion validation.

Why Choose a 1/8 DIN Digital Panel Meter for Quadrature Encoder Input Applications?

Digital Panel Meters, such as the Laureate 1/8 DIN model, offer exceptional precision, robust connectivity, and a compact design, making them ideal for quadrature encoder input applications. Their ability to process bidirectional quadrature signals, provide accurate position and rate measurements, and support features like setpoint control and serial communication ensures reliable performance. Digital Panel Meters integrate seamlessly into modern automation systems, enhancing efficiency, accuracy, and control.

Conclusion

The 1/8 DIN Digital Panel Meter for Quadrature Encoder Input and Bidirectional Position or Rate Applications is a powerful and versatile tool for industrial automation, robotics, manufacturing, renewable energy, and laboratory testing. Its high-precision 6-digit display, ±0.005% accuracy, and advanced features like programmable scaling and Modbus connectivity ensure reliable motion control measurements. Operating from -40°C to 70°C with CE/RoHS3 compliance, Digital Panel Meters are a cornerstone of modern motion monitoring systems, supporting accuracy and efficiency across diverse industries.

Less Information.