Digital Panel Meter for Process & Ratiometric Applications

Ratiometric potentiometer follower application

In this application shown, the signal from a sliding contact voltage divider can be converted to engineering units such as position, level or percentage. By operating in a ratiometric mode, the meter automatically removes any effects caused by variations in the excitation supply. Connect excitation return to signal return, and jumper the excitation output to 5 Vdc.

|

|

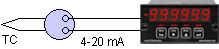

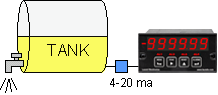

Powering two-wire transmitters |

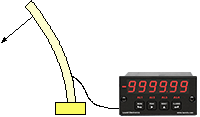

Testing with peak detection |

|

|

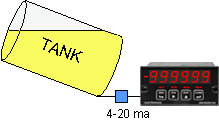

Custom curve linearization |

Rate from successive readings |

Sample Applications for Process and Ratiometric Applications Using the 1/8 DIN Digital Panel Meter

Introduction

In industrial automation and process control, accurate measurement of process variables and their ratios is essential for optimizing efficiency and ensuring product quality. Digital Panel Meters, such as the 1/8 DIN Digital Panel Meter for Process and Ratiometric Applications from Laurel Electronics’ Laureate series, are engineered to process analog signals (e.g., 4-20 mA, 0-10 V) and ratiometric inputs from sensors like strain gauges or potentiometers. With a 5- or 6-digit LED display, ±0.01% accuracy, and robust connectivity, this Digital Panel Meter is ideal for monitoring and controlling process parameters. This section explores where and how Digital Panel Meters are used in process and ratiometric applications, along with specific use cases, highlighting their vital role in industrial and laboratory settings.

Understanding DIN Standards

The term "DIN" refers to the Deutsches Institut für Normung, the German Institute for Standardization, which defines global standards for industrial components. The "1/8 DIN" designation signifies a compact size, with the Digital Panel Meter’s front panel measuring approximately 48 x 96 mm (1.89 x 3.78 inches). This space-efficient design makes Digital Panel Meters perfect for integration into control panels, especially in environments with limited space.

What is a 1/8 DIN Digital Panel Meter for Process and Ratiometric Applications?

The 1/8 DIN Digital Panel Meter for Process and Ratiometric Applications is a versatile device designed to handle analog signals (e.g., 4-20 mA, 0-10 V, 0-5 V) and ratiometric inputs from sensors like strain gauges, potentiometers, or bridges. It features a high-impedance input (1 GΩ for ±200 mV and ±2 V ranges) and supports ratiometric operation to compensate for excitation voltage variations. Equipped with programmable scaling, auto-tare, setpoint control, and serial communication (RS-232, RS-485, Modbus), this Digital Panel Meter is a key component for precise process monitoring and control in industrial automation.

How Is It Used?

Digital Panel Meters process analog or ratiometric signals to provide accurate measurements of process variables or their ratios, integrating seamlessly into control systems. The operational process includes:

-

Signal Acquisition: Captures process signals (4-20 mA, 0-10 V, 0-5 V) or ratiometric inputs from sensors like strain gauges or potentiometers, with jumper-selectable ranges from ±200 mV to ±600 V or ±2 mA to ±5 A.

-

Signal Processing: Employs Concurrent Slope analog-to-digital conversion with a 60 Hz update rate to transform signals into digital values, using digital filtering for stability and noise rejection.

-

Display: Presents measurements on a 5- or 6-digit LED display, scalable to engineering units (e.g., psi, °C, mm) from -99,999 to +99,999 or -999,999 to +999,999, with ±0.01% accuracy.

-

Output and Control: Offers dual 8A relays for setpoint control, a 4-20 mA or 0-10 V analog output, and serial communication (RS-232, RS-485, Modbus) for integration with PLCs or SCADA systems.

-

Excitation Supply: Provides isolated 5 V, 10 V, or 24 V excitation to power transducers or two-wire transmitters, with ratiometric mode ensuring stable readings despite excitation variations.

Where Is a 1/8 DIN Digital Panel Meter for Process and Ratiometric Applications Used?

Digital Panel Meters are utilized in environments requiring precise measurement of process variables or ratios, spanning industrial, laboratory, and commercial settings. Their compact size and high accuracy make them ideal for:

-

Industrial Process Control: Employed in manufacturing plants to monitor process variables like pressure or flow, ensuring operational efficiency with Digital Panel Meters.

-

Laboratory Research: Used in scientific experiments to measure ratios or absolute values from sensors, supported by Digital Panel Meters’ high-resolution displays.

-

Energy Management: Monitors power consumption or voltage ratios in energy systems, facilitated by Digital Panel Meters’ reliable performance.

-

HVAC Systems: Tracks temperature or pressure for environmental control, with Digital Panel Meters enhancing accuracy.

-

Chemical Processing: Measures flow or pressure ratios to ensure precise material blending, supported by Digital Panel Meters’ ratiometric capabilities.

Applications for Process and Ratiometric Use Cases

- Industrial Automation

- Process Monitoring: Digital Panel Meters track process variables like pressure, flow, or temperature from 4-20 mA or 0-10 V signals, ensuring processes remain within specified limits for quality control.

- Ratio Control: Digital Panel Meters calculate the ratio of two inputs (e.g., flow rates) to regulate mixing processes, such as chemical blending in manufacturing.

- Chemical and Pharmaceutical Processing

- Flow Ratio Measurement: Digital Panel Meters measure the ratio of two flow rates to ensure accurate chemical dosing, maintaining product consistency and safety.

- Pressure Monitoring: Digital Panel Meters monitor absolute or relative pressure in reactors, using ratiometric mode for stable readings despite excitation variations.

- Energy Management

- Power Consumption Tracking: Digital Panel Meters monitor current or voltage from 4-20 mA signals, optimizing energy usage in industrial facilities.

- Voltage Ratio Analysis: Digital Panel Meters measure voltage ratios in power systems to assess efficiency and stability.

- HVAC Systems

- Temperature Control: Digital Panel Meters display temperature from sensors, ensuring optimal conditions in heating or cooling systems.

- Pressure Ratio Monitoring: Digital Panel Meters track pressure ratios in HVAC ducts to maintain efficient airflow and energy use.

- Laboratory Research

- Sensor Calibration: Digital Panel Meters measure ratios from potentiometers or strain gauges in experimental setups, ensuring accurate data for research outcomes.

- Process Variable Testing: Digital Panel Meters monitor absolute values like temperature or pressure in controlled experiments, supporting precise analysis.

Why Choose a 1/8 DIN Digital Panel Meter for Process and Ratiometric Applications?

Digital Panel Meters, such as the Laureate 1/8 DIN model, offer unmatched precision, robust connectivity, and a compact design, making them ideal for process and ratiometric applications. Their ability to process a wide range of signals, provide stable excitation, and support features like programmable scaling, setpoint control, and serial communication ensures accurate and reliable measurements. Digital Panel Meters integrate seamlessly into modern automation systems, enhancing efficiency, quality, and control.

Conclusion

The 1/8 DIN Digital Panel Meter for Process and Ratiometric Applications is a powerful and versatile tool for industrial automation, chemical processing, energy management, HVAC systems, and laboratory research. Its high-precision 5- or 6-digit display, ±0.01% accuracy, and advanced features like ratiometric operation and Modbus connectivity ensure reliable measurement of process variables and ratios. Operating from -40°C to 70°C with CE/RoHS3 compliance, Digital Panel Meters are a cornerstone of modern process control and monitoring systems, supporting accuracy and efficiency across diverse industries.

Less Information.