Digital Panel Meter for Time Interval of Periodic Events Applications

| Time Interval Mode for Time Delay | |

|---|---|

|

For periodic pulses applied to A and B channels, time delays can be measured down to 0.2 µs resolution from the rising or falling edge of A to the rising or falling edge of B (selectable). |

| Time Interval Mode for Pulse Width | |

|

The width of periodic pulses (t1 or t2) can be measured by tying the A and B channels together. As for time delay, readings are averaged over a user-selectable gate time. |

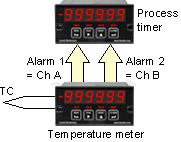

| Timing Process Dynamics with a Panel Meter and Time Interval Meter | |

|

The start and stop pulses used for timing can be generated by the dual relay board in a Laureate panel meter or digital counter. For instance, the start and stop pulse edges can be created as temperature passes two alarm setpoints, or temperature cycles in a hysteresis control mode. |

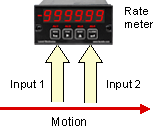

| Rate Based on 1 / Time | |

|

The Extended stopwatch meter can be programmed to display highly accurate rate based on elapsed time. A pulse or switch closure can initiate timing, while another pulse or switch closure stops timing. The meter can be programmed with multipliers to display rate in appropriate engineering units, such as meters/sec, for any time duration. |

| Replacing an Oscilloscope with a Laureate Time Interval Meter | |

|

An oscilloscope is great for viewing and timing pulses in a lab. However, in fixed installations where digital timing accuracy and control outputs are required, a low-cost Laureate time interval meter will be the instrument of choice. Resolution to 0.2 µs is feasible. |

| Instrumenting a Pulsed Laser System Using Laureate Counters | |

|

|

| Some of the many possibilities in instrumenting a pulsed laser system with Laureate dual-channel counters. | |

Sample Applications for Time Interval Applications Using the 1/8 DIN Digital Panel Meter

Introduction

In industrial automation, laboratory research, and process control, precise measurement of time intervals between events is critical for optimizing efficiency, ensuring quality, and maintaining safety. Digital Panel Meters, such as the 1/8 DIN Digital Panel Meter for Time Interval from Laurel Electronics’ Laureate series, are designed to measure and display time intervals with high accuracy. Featuring a 6-digit LED display, ±2 ppm accuracy, and robust connectivity, this Digital Panel Meter is ideal for time interval applications. This section explores where and how Digital Panel Meters are used in time interval applications, along with specific use cases, highlighting their essential role in industrial and scientific settings.

Understanding DIN Standards

The term "DIN" refers to the Deutsches Institut für Normung, the German Institute for Standardization, which establishes global standards for industrial components. The "1/8 DIN" designation indicates a compact size, with the Digital Panel Meter’s front panel measuring approximately 48 x 96 mm (1.89 x 3.78 inches). This space-efficient design makes Digital Panel Meters ideal for integration into control panels, particularly in environments with limited space.

What is a 1/8 DIN Digital Panel Meter for Time Interval Applications?

The 1/8 DIN Digital Panel Meter for Time Interval is a high-precision device optimized for measuring the duration between two events, such as start and stop pulses from sensors. It supports timing ranges from 1 µs to 999,999 hours with a 6-digit display offering resolutions up to ±999,999 counts. Equipped with features like programmable timing modes, setpoint control, and serial communication (RS-232, RS-485, Modbus), this Digital Panel Meter is a key tool for precise time interval measurement in industrial automation.

How Is It Used?

Digital Panel Meters measure and display time intervals, integrating seamlessly into control systems for precise timing applications. The operational process includes:

-

Signal Acquisition: Captures start and stop pulses from sensors like NPN/PNP switches, contact closures, or AC signals (12 mV to 250 V), with jumper-selectable input ranges.

-

Signal Processing: Employs a high-speed counter with a quartz crystal time base to measure time intervals with ±2 ppm accuracy, updating at 60 conversions per second.

-

Display: Shows time intervals on a 6-digit LED display in HH.MM.SS or decimal format (e.g., seconds, milliseconds) from -999,999 to +999,999, with customizable formats.

-

Output and Control: Provides dual 8A relays for setpoint control (e.g., timing alarms), a 4-20 mA or 0-10 V analog output, and serial communication (RS-232, RS-485, Modbus) for integration with PLCs or SCADA systems.

-

Timing Modes: Supports programmable settings for start, stop, or reset functions, ensuring flexibility for various timing applications.

Where Is a 1/8 DIN Digital Panel Meter for Time Interval Applications Used?

Digital Panel Meters are deployed in environments requiring precise measurement of time intervals, spanning industrial, laboratory, and commercial settings. Their compact size and high accuracy make them ideal for:

-

Industrial Automation: Used in manufacturing plants to time process cycles, ensuring efficiency with Digital Panel Meters.

-

Laboratory Research: Measures experiment durations, with Digital Panel Meters supporting accurate data collection.

-

Automotive Testing: Tracks timing intervals in engine or component testing, with Digital Panel Meters enhancing precision.

-

Building Management Systems: Monitors timing for HVAC operations, with Digital Panel Meters ensuring efficiency.

-

Process Control: Measures intervals in production processes, supported by Digital Panel Meters’ reliable performance.

Applications for Time Interval Use Cases

- Industrial Automation

- Process Cycle Timing: Digital Panel Meters measure the duration of production cycles in manufacturing, ensuring consistent output and efficiency.

- Equipment Synchronization: Digital Panel Meters time intervals between automated processes to maintain coordination and minimize delays.

- Laboratory Research

- Experimental Timing: Digital Panel Meters track durations of chemical reactions or physical tests, ensuring accurate data for research outcomes.

- Equipment Calibration: Digital Panel Meters measure calibration cycle times, supporting precise instrument validation.

- Automotive Testing

- Engine Cycle Timing: Digital Panel Meters measure intervals between engine cycles, ensuring performance optimization during testing.

- Component Response Timing: Digital Panel Meters track response times of automotive components for quality assurance.

- Building Management Systems

- HVAC Timing: Digital Panel Meters monitor timing intervals for HVAC operations, ensuring efficient heating or cooling cycles.

- Maintenance Scheduling: Digital Panel Meters track intervals for equipment servicing, preventing failures and optimizing performance.

- Process Control

- Batch Process Timing: Digital Panel Meters measure intervals in batch processes, such as mixing or filling, to ensure consistent quality.

- System Monitoring: Digital Panel Meters track timing intervals in production systems to detect irregularities and optimize efficiency.

Why Choose a 1/8 DIN Digital Panel Meter for Time Interval Applications?

Digital Panel Meters, such as the Laureate 1/8 DIN model, offer exceptional precision, robust connectivity, and a compact design, making them ideal for time interval applications. Their ability to measure precise time intervals, support programmable modes, and provide serial communication ensures reliable performance. Digital Panel Meters integrate seamlessly into modern automation systems, enhancing efficiency, accuracy, and control.

Conclusion

The 1/8 DIN Digital Panel Meter for Time Interval Applications is a powerful and versatile tool for industrial automation, laboratory research, automotive testing, building management, and process control. Its high-precision 6-digit display, ±2 ppm accuracy, and advanced features like programmable timing modes and Modbus connectivity ensure reliable time interval measurements. Operating from -40°C to 70°C with CE/RoHS3 compliance, Digital Panel Meters are a cornerstone of modern timing systems, supporting accuracy and efficiency across diverse industries.

Less Information.