Digital Panel Meter for Batch Controller Pulse Input Applications

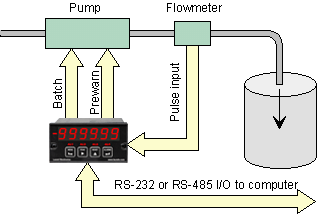

| Drum Filling Application Utilizing Two Relay Outputs | |

|---|---|

|

In this drum filling application, the Laureate pulse-input batch controller utilizes uses its two relays to control a pump. The Prewarn relay slows down the pump near the preset to avoid overshoot. The Batch relay stops the pump at the preset. |

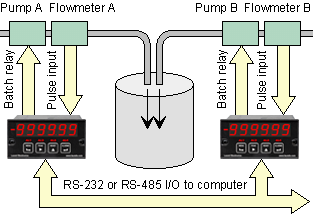

| Controlling Chemical Mixing of Materials | |

|

Multiple Laureate batch controllers can be used in combination to control the mixing of materials in the proper ratio. Each feed line is equipped with its own pump, flowmeter, and Laureate. Controller setup and monitoring of the mixing operation are facilitated by optional serial communications. RS485 allows a single data line to handle multiple controllers. |

| Up-Counting Batch Control | |

|

In up-counting batch control, the Laureate counts up from zero to a preset maximum. A prewarn level is available to slow down filling near the preset to avoid overshoot. A time delay can be programmed from the end of each batch to the start of the next batch. |

| Down-Counting Batch Control | |

|

In down-counting batch control, the Laureate counts down from the preset maximum to zero. A prewarn level is available to slow down filling or emptying near zero. Again, a time delay can be programmed from the end of each batch to the start of the next batch. |

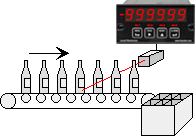

| Discrete Filling and Batch Counting | |

|

The Laureate batch controller is ideal for discrete manufacturing as well as repetitive fill operations. In this example, the Laureate counts bottles which it then groups into sixpacks. Its Grand Total capability can be used to track bottles or sixpacks. |

Sample Applications for Batch Controller Pulse Input Applications Using the 1/8 DIN Digital Panel Meter

Introduction

In industrial automation, manufacturing, and process control, precise batch control is essential for ensuring consistent material dispensing and maintaining product quality. Digital Panel Meters, such as the 1/8 DIN Digital Panel Meter for Batch Controller, Pulse Input from Laurel Electronics’ Laureate series, are designed to process pulse signals from sensors like flow meters or counters, enabling accurate batching operations. Featuring a 6-digit LED display, ±0.005% accuracy, and robust connectivity, this Digital Panel Meter is ideal for batch controller applications. This section explores where and how Digital Panel Meters are used in batch controller pulse input applications, along with specific use cases, highlighting their critical role in industrial settings.

Understanding DIN Standards

The term "DIN" refers to the Deutsches Institut für Normung, the German Institute for Standardization, which establishes global standards for industrial components. The "1/8 DIN" designation indicates a compact size, with the Digital Panel Meter’s front panel measuring approximately 48 x 96 mm (1.89 x 3.78 inches). This space-efficient design makes Digital Panel Meters ideal for integration into control panels, particularly in environments with limited space.

What is a 1/8 DIN Digital Panel Meter for Batch Controller Pulse Input Applications?

The 1/8 DIN Digital Panel Meter for Batch Controller, Pulse Input is a high-precision device optimized for counting pulse signals from sensors like flow meters, proximity switches, or encoders to control batch processes. It supports input frequencies from 0.005 Hz to 1 MHz and offers a 6-digit display with resolutions up to ±999,999 counts. Equipped with features like programmable setpoints, batch control modes, and serial communication (RS-232, RS-485, Modbus), this Digital Panel Meter is a key tool for precise material dispensing in industrial automation.

How Is It Used?

Digital Panel Meters process pulse signals to control and monitor batch processes, integrating seamlessly into control systems. The operational process includes:

-

Signal Acquisition: Captures pulse signals from sensors like NPN/PNP proximity switches, contact closures, or AC signals (12 mV to 250 V AC), with jumper-selectable input ranges.

-

Signal Processing: Employs a high-speed counter with a quartz crystal time base to count pulses, calculating batch totals with ±0.005% accuracy and a 60 Hz update rate, with digital filtering to reduce noise.

-

Display: Shows batch counts or totals on a 6-digit LED display, scalable to engineering units (e.g., liters, units) from -999,999 to +999,999, with customizable formats.

-

Output and Control: Provides dual 8A relays for setpoint control (e.g., stopping batch at target count), a 4-20 mA or 0-10 V analog output, and serial communication (RS-232, RS-485, Modbus) for integration with PLCs or SCADA systems.

-

Batch Control: Supports programmable batch setpoints and modes (e.g., auto-reset, pause, or stop), ensuring precise control of material dispensing.

Where Is a 1/8 DIN Digital Panel Meter for Batch Controller Pulse Input Applications Used?

Digital Panel Meters are deployed in environments requiring precise batch control of materials using pulse signals, spanning industrial, manufacturing, and processing settings. Their compact size and high accuracy make them ideal for:

-

Industrial Process Control: Used in manufacturing plants to control batch dispensing of liquids or materials, ensuring efficiency with Digital Panel Meters.

-

Food and Beverage Industry: Manages batching of ingredients or products, with Digital Panel Meters ensuring consistency and compliance.

-

Water Treatment: Controls chemical dosing for water quality, supported by Digital Panel Meters’ reliable performance.

-

Chemical Processing: Regulates material quantities in chemical production, with Digital Panel Meters enhancing accuracy.

-

Packaging Systems: Monitors and controls filling operations, with Digital Panel Meters providing precise batch control.

Applications for Batch Controller Pulse Input Use Cases

- Industrial Automation

- Batch Dispensing: Digital Panel Meters control the dispensing of materials like liquids or powders in manufacturing, using pulse signals from flow meters to trigger setpoints for precise batch sizes.

- Production Line Control: Digital Panel Meters manage batch counts in automated systems, ensuring consistent output and minimizing waste.

- Food and Beverage Processing

- Ingredient Batching: Digital Panel Meters measure pulse signals from flow meters to batch ingredients like syrup or flour, ensuring consistent product quality.

- Packaging Filling: Digital Panel Meters control filling operations for containers, such as bottles or bags, to meet regulatory standards and ensure accuracy.

- Water Treatment

- Chemical Dosing: Digital Panel Meters regulate chemical dosing by counting pulses from dosing pumps, ensuring precise water treatment processes.

- Flow Batching: Digital Panel Meters control water flow batches for treatment systems, supporting regulatory compliance.

- Chemical Processing

- Chemical Batching: Digital Panel Meters manage batch quantities of chemicals, using pulse signals to ensure accurate mixing ratios.

- Process Optimization: Digital Panel Meters monitor batch totals to optimize chemical production efficiency.

- Packaging Systems

- Container Filling: Digital Panel Meters control the filling of containers with liquids or solids, ensuring precise volumes for customer satisfaction.

- Quality Control: Digital Panel Meters track batch counts to verify consistent filling quantities across packaging lines.

Why Choose a 1/8 DIN Digital Panel Meter for Batch Controller Pulse Input Applications?

Digital Panel Meters, such as the Laureate 1/8 DIN model, offer exceptional precision, robust connectivity, and a compact design, making them ideal for batch controller pulse input applications. Their ability to process pulse signals, manage batch setpoints, and support features like setpoint control and serial communication ensures reliable performance. Digital Panel Meters integrate seamlessly into modern automation systems, enhancing efficiency, accuracy, and control.

Conclusion

The 1/8 DIN Digital Panel Meter for Batch Controller Pulse Input Applications is a powerful and versatile tool for industrial automation, food processing, water treatment, chemical processing, and packaging systems. Its high-precision 6-digit display, ±0.005% accuracy, and advanced features like programmable setpoints and Modbus connectivity ensure reliable batch control. Operating from -40°C to 70°C with CE/RoHS3 compliance, Digital Panel Meters are a cornerstone of modern batch processing systems, supporting accuracy and efficiency across diverse industries.

Less Information.