Digital Panel Meter for Rate & Totalizer with Functions A+B, A-B, AxB, A/B, A/B-1 Applications

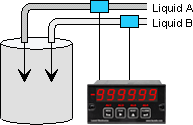

| Controlling the Mixing Ratio of Two Fluids | |

|---|---|

|

Displaying and alarming the input flow rate ratio of two fluids (gas or liquid) allows these to be mixed in a predetermined ratio in continuous processes. The sensing element is normally a turbine flowmeter, which outputs pulses at a frequency proportional to flow rate. The A/B ratio can also be displayed for totalized rate (or delivered volume). |

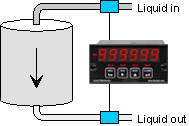

| Computing Net Fluid Inflow & Outflow | |

|

The ratio of the inflow and outflow rates of a tank is a measure of the relative filling or emptying rate. The same meter can also be programmed to display the net inflow or outflow rate in flow units, or to display totalized inflow our outflow in volume units. Any of these parameters can be alarmed using the dual relay board and be transmitted via 4-20 mA, RS232 or RS485. |

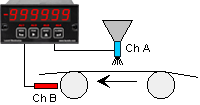

| Controlling Coating Thickness on a Film | |

|

In this application, Channel A measures the rate at which a coating material is applied, as measured by a flow meter, while Channel B measures the speed of the film based on pulses from a proximity switch. Displaying and alarming the A/B ratio assures that an even thickness of coating material is applied as the speed of the film is varies. |

| Synchronizing Two Conveyor Lines | |

|

The dual-channel Laureate counter can measure the speed of conveyor lines by using the output of proximity switches which sense gear teeth or spokes of rotating drive wheels. Displaying the speed ratio of two lines allows line speeds to be adjusted so that material arrives at work stations when needed. |

| Measuring Draw for Elongation | |

|

Draw (Ch A / Ch B - 1) can be used to display the elongation of films compressed between rollers, the shrinkage films, and the RPM difference of rollers whose speed is varied to maintain tension. The six-digit resolution of the Laureate dual channel counter / rate meter is ideal for comparison of rates that are close to each other. |

Sample Applications for Rate and Totalizer Applications with Functions A+B, A-B, A×B, A/B, A/B-1 Using the 1/8 DIN Digital Panel Meter

Introduction

In industrial automation, manufacturing, and process control, precise measurement of rates, totals, and their arithmetic relationships is critical for optimizing efficiency and ensuring product quality. Digital Panel Meters, such as the 1/8 DIN Digital Panel Meter for Rate, Totalizer, and Functions A+B, A-B, A×B, A/B, A/B-1 from Laurel Electronics’ Laureate series, are designed to process dual-channel pulse inputs, performing arithmetic operations like sum, difference, product, ratio, and deviation. Featuring a 6-digit LED display, ±0.01% accuracy, and robust connectivity, this Digital Panel Meter is ideal for complex rate and totalizer applications. This section explores where and how Digital Panel Meters are used in these applications, along with specific use cases, highlighting their essential role in industrial settings.

Understanding DIN Standards

The term "DIN" refers to the Deutsches Institut für Normung, the German Institute for Standardization, which establishes global standards for industrial components. The "1/8 DIN" designation indicates a compact size, with the Digital Panel Meter’s front panel measuring approximately 48 x 96 mm (1.89 x 3.78 inches). This space-efficient design makes Digital Panel Meters ideal for integration into control panels, particularly in environments with limited space.

What is a 1/8 DIN Digital Panel Meter for Rate, Totalizer, and Functions A+B, A-B, A×B, A/B, A/B-1 Applications?

The 1/8 DIN Digital Panel Meter for Rate, Totalizer, and Functions A+B, A-B, A×B, A/B, A/B-1 is a versatile device optimized for processing dual-channel pulse inputs from sensors like flow meters or tachometers, performing arithmetic operations such as sum (A+B), difference (A-B), product (A×B), ratio (A/B), and relative deviation (A/B-1). It supports input frequencies from 0.005 Hz to 1 MHz and offers a 6-digit display with resolutions up to ±999,999 counts. Equipped with features like programmable scaling, setpoint control, and serial communication (RS-232, RS-485, Modbus), this Digital Panel Meter is a key tool for advanced rate and totalizer monitoring in industrial automation.

How Is It Used?

Digital Panel Meters process dual-channel pulse signals to deliver accurate rate, total, and arithmetic function data, integrating seamlessly into control systems. The operational process includes:

-

Signal Acquisition: Captures pulse signals from sensors like NPN/PNP proximity switches, contact closures, or AC signals (12 mV to 250 V AC), with jumper-selectable input ranges for two channels (A and B).

-

Signal Processing: Employs a high-speed counter with a quartz crystal time base to calculate rates, totals, or arithmetic functions (A+B, A-B, A×B, A/B, A/B-1), with ±0.01% accuracy and a 60 Hz update rate.

-

Display: Shows measurements on a 6-digit LED display, scalable to engineering units (e.g., gallons/min, total liters) from -999,999 to +999,999, with customizable formats.

-

Output and Control: Provides dual 8A relays for setpoint control (e.g., alarms for rate deviations), a 4-20 mA or 0-10 V analog output, and serial communication (RS-232, RS-485, Modbus) for integration with PLCs or SCADA systems.

-

Signal Conditioning: Supports digital filtering to reduce noise and programmable gate times for precise measurement control, ensuring stable readings.

Where Is a 1/8 DIN Digital Panel Meter for Rate, Totalizer, and Functions A+B, A-B, A×B, A/B, A/B-1 Applications Used?

Digital Panel Meters are deployed in environments requiring precise measurement of rates, totals, or their arithmetic relationships, spanning industrial, manufacturing, and processing settings. Their compact size and high accuracy make them ideal for:

-

Industrial Process Control: Used in manufacturing plants to monitor flow rates, totals, or ratios, ensuring efficiency with Digital Panel Meters.

-

Chemical Processing: Measures flow or production ratios for precise material blending, supported by Digital Panel Meters’ robust capabilities.

-

Energy Management: Tracks power consumption or production rates, with Digital Panel Meters enhancing accuracy.

-

Water Treatment: Monitors flow rates and totals for regulatory compliance, with Digital Panel Meters providing reliable performance.

-

Manufacturing Automation: Analyzes production metrics like total output or rate differences, supported by Digital Panel Meters’ arithmetic functions.

Applications for Rate and Totalizer Use Cases

- Industrial Automation

- Flow Rate Monitoring: Digital Panel Meters measure flow rates from dual flow meters (e.g., gallons/min) and perform A+B to calculate total flow or A-B to determine net flow, ensuring process efficiency.

- Production Rate Control: Digital Panel Meters track production rates on manufacturing lines, using A/B to monitor ratio consistency for quality control.

- Chemical Processing

- Flow Ratio Measurement: Digital Panel Meters calculate the ratio (A/B) of two flow rates to ensure accurate chemical dosing for consistent blending.

- Totalizer Tracking: Digital Panel Meters accumulate totals (A+B) from two chemical streams to monitor batch quantities.

- Energy Management

- Power Calculation: Digital Panel Meters use A×B to compute power by multiplying current and voltage inputs, optimizing energy usage.

- Consumption Monitoring: Digital Panel Meters track total energy consumption (A+B) from dual meters for cost allocation.

- Water Treatment

- Flow Totalization: Digital Panel Meters accumulate flow totals from water treatment systems, ensuring compliance with regulatory standards.

- Ratio Analysis: Digital Panel Meters measure A/B to control chemical dosing ratios for water quality management.

- Manufacturing Automation

- Production Metrics: Digital Panel Meters calculate differences (A-B) between total and defective parts to monitor quality on production lines.

- Deviation Analysis: Digital Panel Meters use A/B-1 to measure percentage deviations in production rates, ensuring process stability.

Why Choose a 1/8 DIN Digital Panel Meter for Rate, Totalizer, and Functions A+B, A-B, A×B, A/B, A/B-1 Applications?

Digital Panel Meters, such as the Laureate 1/8 DIN model, offer exceptional precision, robust connectivity, and a compact design, making them ideal for rate and totalizer applications with arithmetic functions. Their ability to process dual-channel pulse signals, perform complex calculations, and support features like setpoint control and serial communication ensures reliable performance. Digital Panel Meters integrate seamlessly into modern automation systems, enhancing efficiency, accuracy, and control.

Conclusion

The 1/8 DIN Digital Panel Meter for Rate, Totalizer, and Functions A+B, A-B, A×B, A/B, A/B-1 is a powerful and versatile tool for industrial automation, chemical processing, energy management, water treatment, and manufacturing. Its high-precision 6-digit display, ±0.01% accuracy, and advanced features like arithmetic functions and Modbus connectivity ensure reliable measurement of rates, totals, and their relationships. Operating from -40°C to 70°C with CE/RoHS3 compliance, Digital Panel Meters are a cornerstone of modern process monitoring and control systems, supporting accuracy and efficiency across diverse industries.

Less Information.