Digital Panel Meter for Thermocouple Temperature Applications

Operation as a 4-20 mA Transmitter

With the optional analog output board, Laureate temperature meters can serve as superb, isolated 4-20 mA transmitters. The analog output is scaled to the display, which is linearized to °C or °F and is exceptionally accurate. The analog output further tracks the high read rate of the meter, at up to 60 readings per second at 60 Hz power. Fast update rates are beneficial in many closed-loop and PID control applications.

|

|

Operation as a Fast Controller

With the dual contact relay or dual solid state relay output board options, Laureate temperature meters can serve as extremely fast and accurate ON/OFF controllers for closed-loop temperature control. Multiple setpoint operating modes are individually selectable for each relay, as explained in the dual-setpoint controller section. Relay duty cycles and chatter can be minimized with programmable hysteresis and time delays. High duty cycles and extremely fast response times are possible with the solid state relay, which has a typical response time of only 17 ms.

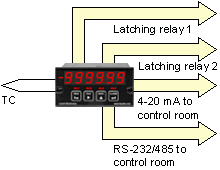

Operation as a Supervisory Monitor

By using the optional dual contact relay or dual solid state relay output options, Laureate temperature meters can monitor processes and provide alarms or shutoffs when these processes exceed normal limits. A band deviation operating mode can be selected for each relay, where an alarm is generated whenever the reading is a selected number of counts above or below the setpoint. Relay operation can be selected as latching or non-latching. When an alarm or shutdown condition is reached, a latched output will remain in the alarm condition until it is reset by a front panel pushbutton, via the serial interface, or via the rear connector.

Sample Applications for Thermocouple Temperature Applications Using the 1/8 DIN Digital Panel Meter

Introduction

In industrial automation, laboratory research, and environmental control, accurate temperature measurement is critical for ensuring process efficiency, product quality, and safety. Digital Panel Meters, such as the 1/8 DIN Digital Panel Meter for Thermocouple Temperature from Laurel Electronics’ Laureate series, are designed to interface with thermocouple sensors, providing precise temperature readings. Featuring a 5-digit LED display, ±0.2°C accuracy, and robust connectivity, this Digital Panel Meter is ideal for thermocouple-based temperature monitoring. This section explores where and how Digital Panel Meters are used in thermocouple temperature applications, along with specific use cases, highlighting their essential role in industrial and scientific settings.

Understanding DIN Standards

The term "DIN" refers to the Deutsches Institut für Normung, the German Institute for Standardization, which establishes global standards for industrial components. The "1/8 DIN" designation indicates a compact size, with the Digital Panel Meter’s front panel measuring approximately 48 x 96 mm (1.89 x 3.78 inches). This space-efficient design makes Digital Panel Meters ideal for integration into control panels, particularly in environments with limited space.

What is a 1/8 DIN Digital Panel Meter for Thermocouple Temperature Applications?

The 1/8 DIN Digital Panel Meter for Thermocouple Temperature is a high-precision device optimized for processing signals from thermocouple sensors (types J, K, T, E, N, R, S), delivering accurate temperature measurements in °C or °F. It supports input ranges from -270°C to 1820°C (type-dependent) with 0.1°C or 1°C resolution and includes cold junction compensation for enhanced accuracy. Equipped with features like programmable scaling, setpoint control, and serial communication (RS-232, RS-485, Modbus), this Digital Panel Meter is a key tool for temperature monitoring in industrial automation.

How Is It Used?

Digital Panel Meters process thermocouple signals to deliver accurate temperature data, integrating seamlessly into control systems. The operational process includes:

-

Signal Acquisition: Receives microvolt signals from thermocouple sensors (e.g., type K for -200°C to 1350°C), with automatic cold junction compensation to account for ambient temperature variations.

-

Signal Processing: Employs a high-speed analog-to-digital converter (ADC) with a 60 Hz update rate to convert thermocouple signals into temperature values, using digital filtering to eliminate noise and ensure stability.

-

Display: Shows temperature on a 5-digit LED display, scalable to °C or °F from -99,999 to +99,999, with ±0.2°C accuracy and 0.1°C resolution for precise readings.

-

Output and Control: Provides dual 8A relays for setpoint control (e.g., temperature alarms), a 4-20 mA or 0-10 V analog output, and serial communication (RS-232, RS-485, Modbus) for integration with PLCs or SCADA systems.

-

Excitation Supply: Supports external sensor integration without requiring additional power, leveraging the meter’s isolated power options for stable operation.

Where Is a 1/8 DIN Digital Panel Meter for Thermocouple Temperature Applications Used?

Digital Panel Meters are deployed in environments requiring precise temperature measurement using thermocouples, spanning industrial, laboratory, and commercial settings. Their compact size and high accuracy make them ideal for:

-

Industrial Process Control: Used in manufacturing plants to monitor temperature in processes like heat treatment or chemical reactions, ensuring efficiency with Digital Panel Meters.

-

Laboratory Research: Employed in scientific experiments to measure temperatures accurately, supported by Digital Panel Meters’ high-resolution displays.

-

HVAC Systems: Tracks temperature in heating, ventilation, and air conditioning systems, with Digital Panel Meters enhancing environmental control.

-

Food and Beverage Industry: Monitors temperature in food processing to ensure safety and compliance, with Digital Panel Meters providing reliable performance.

-

Energy Management: Measures temperature in power generation or renewable energy systems, supported by Digital Panel Meters’ robust capabilities.

Applications for Thermocouple Temperature Use Cases

- Industrial Automation

- Heat Treatment Monitoring: Digital Panel Meters measure furnace temperatures using type K or S thermocouples, ensuring precise control for metal hardening or annealing processes.

- Process Temperature Control: Digital Panel Meters monitor reactor temperatures in chemical manufacturing, triggering alarms or control actions to maintain safe conditions.

- Food and Beverage Processing

- Cooking and Pasteurization: Digital Panel Meters track temperatures in ovens or pasteurizers to ensure food safety and quality, using type J or T thermocouples.

- Cold Storage Monitoring: Digital Panel Meters measure freezer or refrigerator temperatures to maintain optimal storage conditions for perishable goods.

- Laboratory Research

- Thermal Experiments: Digital Panel Meters measure temperatures in scientific experiments, such as material testing or chemical reactions, ensuring accurate data collection.

- Equipment Calibration: Digital Panel Meters verify thermocouple performance in calibration setups, supporting precise instrument validation.

- HVAC Systems

- Environmental Control: Digital Panel Meters monitor air or water temperatures in HVAC systems, ensuring efficient heating or cooling operations.

- Energy Efficiency: Digital Panel Meters track temperature variations to optimize HVAC performance and reduce energy consumption.

- Energy Management

- Power Plant Monitoring: Digital Panel Meters measure temperatures in boilers or turbines using type R or S thermocouples, ensuring operational efficiency.

- Renewable Energy Systems: Digital Panel Meters monitor temperatures in solar thermal or geothermal systems, supporting system reliability.

Why Choose a 1/8 DIN Digital Panel Meter for Thermocouple Temperature Applications?

Digital Panel Meters, such as the Laureate 1/8 DIN model, offer exceptional precision, robust connectivity, and a compact design, making them ideal for thermocouple temperature applications. Their ability to process microvolt signals from thermocouples, provide accurate cold junction compensation, and support features like setpoint control and serial communication ensures reliable temperature measurements. Digital Panel Meters integrate seamlessly into modern automation and monitoring systems, enhancing efficiency, safety, and control.

Conclusion

The 1/8 DIN Digital Panel Meter for Thermocouple Temperature Applications is a powerful and versatile tool for industrial automation, food processing, laboratory research, HVAC systems, and energy management. Its high-precision 5-digit display, ±0.2°C accuracy, and advanced features like cold junction compensation and Modbus connectivity ensure reliable temperature measurements. Operating from -40°C to 70°C with CE/RoHS3 compliance, Digital Panel Meters are a cornerstone of modern temperature monitoring systems, supporting accuracy and efficiency across diverse industries.

Less Information.