Digital Counters & Timers High-Performance Industrial Readouts & Controls

Frequency, Rate Meter, Flow Rate Indicator

Two independent scalable pulse-input channels A and B from 0 Hz to 1 MHz. Channels may be combined arithmetically. One channel can display rate while other displays total. High read rate for control applications: AC line frequency can be measured to 60.0000 Hz in a few line cycles. Ideal for use as a tachometer or readout of a turbine flow meter.

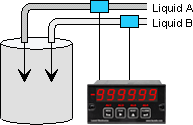

Totalizer (pulse input)

Two independent scalable pulse-input channels A and B. Count up or down to a preset at rates up to 1 MHz. Get scaled rate and total from the same pulse signals. Scalable for direct readout in engineering units, such as gallons or cubic feet based on counts from a turbine flow meter. One channel can display total while other displays rate.

Process Totalizer (analog input)

Displays and totalizes 0-1 mA, 4-20 mA, or 0-10 V analog process signals. For example, displays total from the analog 4-20 mA output of a flowmeter. Square root extraction is standard for use with differential pressure flowmeters. 1/8 DIN case, 6-digit LED display, choice of analog output, relay and data I/O options.

Digital Stopwatch

Times single events or processes which produce start and stop pulses. Resolution to 0.2 µs, duration from 1 µs to 999,999 hours. Time may be displayed in microseconds, milliseconds or decimal seconds with 6-digit resolution, or in HH.MM.SS clock format. Also accumulates time of multiple events to 999999 hours and retains power in the absence of power.

Laureate Time Interval Meter

Times periodic events which produce start and stop pulses from 1 µs to 199.99 s over a programmed gate time up to 199.99 s. Timing resolution to 0.2 µs. Optional data I/O and relays for alarm or control. Six 0.56" (14.2 mm) high digits, 1/8 DIN case.A+B, A-B, AxB, A/B, A/B-1 Draw Meter

Arithmetic functions can be applied to individually scalable dual channels A and B. For example, add or subtract rates from two flow meters for combined scaled flow or volume. Display the ratio of flow rates, RPM of rollers, or speed of moving belts for mixing or ratio control. Draw, which is obtained by subtracting 1 from ratio, can be used to indicate elongation or shrinkage of material as it passes between rollers.

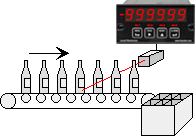

Batch Controller (pulse input)

Low-cost pulse input controller for repetitive fill operations. The typical application utilizes a flow meter input and two built-in relays: a Prewarn relay to slow down the pump near a preset to avoid overshoot, and a Batch relay to stop the pump at the preset. Can display rate or total of individual batches, and total volume or number of all batches.

Batch Controller (analog input)

Same capabilities as pulse-input batch controller for repetitive fill operations, but uses the 0-1 mA, 4-20 mA, 0-10V signal from an analog output flow sensor. Also usable as an analog signal totalizer. For example, display total from a flowmeter with a 4-20 mA analog output.

Phase Angle Meter

Exceptionally fast response (up to 20 updates per second) and high accuracy for low frequencies, such as AC line frequency. A resolution of 1°, 0.1° or 0.01° is user-selectable. Accuracy is 0.01% up to 100 Hz, 0.1% at 1 kHz, and 1% at 10 kHz.

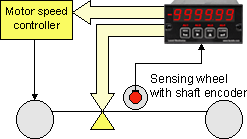

Quadrature Position & Rate Meter

Accepts the A and B quadrature signals from a shaft encoder or linear encoder to display bidirectional scaled position or scaled rate. Accepts 5V or 10V differential or single-ended 5V logic level signals. Counts one, two or four transitions at a combined rate up to 250 kHz. Total or rate can be mathematically scaled for display in engineering units from -999,999 to +999,999. An analog output scaled to the display and relay outputs are optional.

Duty Cycle Meter

Displays ON or OFF period as a percentage of total period over a programmed gate time from 10 ms to 199.99 s. A resolution of 1%, 0.1% or 0.01% is user-selectable. Applications include monitoring time-modulated control systems.

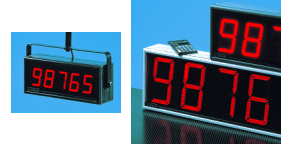

Magna Series 2", 4", 6" or 8" Large-Digit Displays

Available with 57 mm (2.2"), 102 mm (4.0"), 144 mm (5.7") or 200 mm (7.9") digit height and 4 to 6 digits for serial data, timer, totalizer, frequency, rate, clock, process signal, or temperature inputs. RS232, RS485 and relay outputs are optional. Environmentally sealed to NEMA-4 on all sides. Available for indoor or outdoor brightness.