Exceptional flexibility to solve industrial measurement & control problems

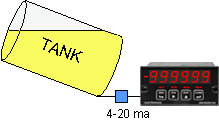

DC Digital Panel Meter

True AC RMS Panel Meter

Process Meter & Analog Ratio Meter

Process Meter & Totalizer

Load Cell, Strain Gage & Microvolt Meter

Scale / Weight Meter

Thermocouple Temperature Meter

RTD Temperature Meter

Ohmmeter

Linearizing Panel Meter

L40 Low-Cost Universal Analog Input Digital Meter

M-35 Microminiature Digital Process Meter

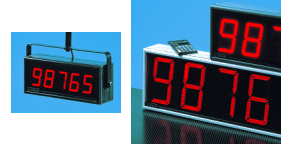

MAGNA Series 2", 4", 6" or 8" Large-Digit Displays

Laureate™ Series Digital Panel Meters

The Laureate Series is Laurel's flagship line of 1/8 DIN programmable 5-digit digital panel meters, 6-digit digital counters and timers, and 6-digit remote displays. Digit height is 14.2 mm (0.56").

Modular design, a wide choice of plug-in options, exceptional accuracy, high speed (up to 60 readings / second), scalability, plus programmable features allow Laureates to be configured for applications from simple monitoring to computer interface and control. Setup can be from the front panel or by using powerful Setup & Calibration Software, which can be downloaded at no charge from our Software Download Page.

Datalogging Software turns a PC connected to up to 31 Laureate digital panel meters or digital counters into a powerful, low-cost datalogging system with virtual meter screen views plus arithmetic and totalizing capabilities.

| Laureate Options | Laureate Downloadable Files | |||||||

|---|---|---|---|---|---|---|---|---|

|

|