Features

- Accepts RS232, RS485 or USB streaming data

- Accuracy of 0.01% of reading ± 2 counts

- Able to extract readings embedded in ASCII data strings

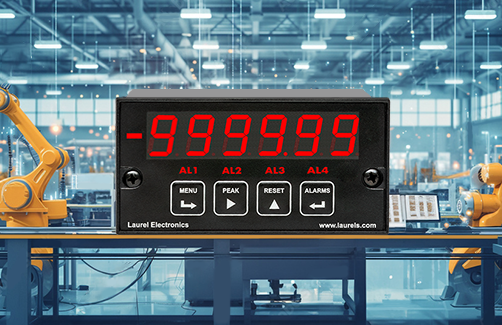

- Displays 6-digit numeric readings with any decimal point

- Up to 60 conversions per second, Ideal for peak or valley capture

- Digital span adjust from 0 to ±99,999, zero adjust from -99,999 to +99,999

- Front panel scalable to ±99,999 for use with current shunts

- 1/8 DIN size with bright red or green 0.56" (14.2mm), high LED digits

- Power 85-264 Vac / 90-300 Vdc or 10-48 Vdc / 12-32 Vac (isolated)

- Operating temperature from -40°C to 70°C (-40°F to 158°F)

- Wide choice of Plug-in-Play options:

- 2 or 4 relays, mechanical or solid state, for alarm or control (isolated)

- 1 or 2 Analog output, 4-20 mA, 0-20 mA, 0-10V, or -10V to +10V (isolated)

- Communications: Ethernet, WiFi, USB, RS232, RS485 (isolated)

Laureate™ 1/8 DIN Digital Panel Meters Remote Displays

(or Serial Input Meters) are slave displays which accept RS232, RS485 or USB data from computers, programmable controllers, Laureate instruments, or other devices with a streaming serial data output. They can also provide relay closures and an analog output based on the received readings. They blend in with 1/8 DIN Laureate digital panel meters, counters and timers to provide a numeric 6-digit display from -999,999 to +999,999.

All signal conditioner board ranges are factory-calibrated, with calibration factors for each range securely stored in an onboard EEPROM. These factors can be scaled via software to accommodate external shunts, enabling field replacement of signal conditioner boards without necessitating recalibration of the associated digital panel meters. For optimal accuracy, factory recalibration is recommended annually. All Laurel Electronics instruments undergo factory calibration using the industry-leading Fluke calibrators, which are recalibrated yearly and certified traceable to national standards, ensuring the highest level of precision and reliability.

Streaming serial data can be generated at rates up to 9600 baud by a weighing scale or other instrument. In particular, it can be generated by Laureate digital panel meters, counter/timer or transmitter. A Remote Display can duplicate the reading of that instrument, or it can be used to display additional data items which can be transmitted serially, but which cannot be shown simultaneously on a single display. For example, while a Laureate counter can only display one selected parameter at a time (such as rate A), it can transmit multiple parameters (such as rate A, rate B, ratio A/B and peak). The Remote Display can be set up to display any serially transmitted item, and an indicator light shows which item has been chosen for display.

Setup of the Remote Display uses Laurel’s free Instrument Setup Software. Selectable modes allow easy interface to other Laureate instruments and extract 1, 2 or 3 data items. For other instruments, readings can be extracted from streaming ASCII strings that contain multiple data values and non-numeric characters, such as Start and Stop characters. Any number of characters between the Start character and the data can be masked Off. Up to 8 display characters (including sign and decimal point) can be masked On. Any number of characters between the last displayed character and the Stop character can be masked Off.

An optional (isolated) analog output board allows the Remote Display to serve as a highly accurate digital-to-analog converter and transmitter.

An optional relay output board with 2 or 4 relays can add remote alarm or control capability. The relays can be 8A contact relays or opto-(isolated) 120 mA AC/DC solid state relays. The relays can respond to the transmitted values or to any of 8 serially transmitted control characters. The control characters can be generated by a Laureate meter, counter or timer, thereby assuring that the local and remote alarm points are identical.

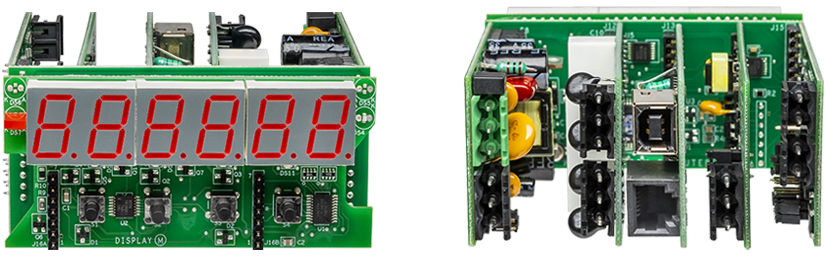

Modular Design for Maximum Flexibility at Minimum Cost

All boards are isolated from meter and power grounds. Optional Plug-in-Play boards for communications and control include Ethernet, WiFi, serial communication boards, dual or quad relay boards, and an analog output board. Laureates may be powered from 85-264 Vac or optionally from 12-32 Vac or 10-48 Vdc. The display is available with bright red or green 0.56" (14.2mm) high LED digits. The 1/8 DIN case meets NEMA 4X (IP65) specifications from the front when panel mounted. Any setup functions and front panel keys can be locked out for simplified usage and security. A built-in 5, 10, 12, or 24 Vdc excitation supply can power transducers, eliminating the need for an external power supply. All power and signal connections are via UL / VDE / CSA rated screw clamp plugs.

The Laureate™ Series features modular design with up to 7 isolated plug-in boards, applicable to all Laureate 1/8 DIN Digital Panel Meters.

Modular Hardware

The design of the Laureate™ Series is modular for maximum flexibility at minimum cost. All boards are isolated from meter and power grounds. The base configuration for a panel meter or counter consists of a main module (with computer and plug-in display boards), a power supply board, and a signal conditioner board. Optional plug-in-play boards include an isolated setpoint controller board, an isolated analog output board, and an isolated digital interface board. Modular design and a choice of plug-in options allow the Laureate to be customized for a broad range of applications from simple monitoring to control and computer interface. There can be up to five plug-in boards in a 1/8 DIN Laureate.

Connecting Laureate Digital Panel Meters to a Local Area Network (LAN)

Up to 30 Laureate Digital Panel Meters and/or LT Transmitters can be configured for RS485 and daisy-chained to an LT Transmitter using Laurel’s High Speed Ethernet-to-RS485 converter board for seamless LAN integration. Alternatively, Laurel LTE series Ethernet transmitters can connect directly to a LAN via an Ethernet cable. Setup for both configurations is streamlined using Laurel’s free Instrument Setup Software, which simplifies node discovery and transmitter configuration.

Flexible Communication Options for Digital Panel Meters

Laureate Digital Panel Meters can be equipped with Laurel communication boards to support various interfaces and protocols. These include serial interfaces with ASCII or Modbus RTU protocols, and Ethernet interfaces with web access, ASCII, or Modbus TCP/IP protocols, ensuring versatile connectivity for your commercial applications.

| Display | |||

|---|---|---|---|

| Readout | 6 LED digits, 7-segment, 14.2 mm (.56"), red or green. | ||

| Range | -999,999 to +999,999 | ||

| Indicators | Four LED lamps | ||

| * Range not ETL certified. | |||

| Recalibration: All ranges are calibrated at the factory. Recalibration is recommended every 12 months. | |||

| Power | |||

| Voltage, standard | 85-264 Vac or 90-300 Vdc | ||

| Voltage, optional | 12-32 Vac or 10-48 Vdc | ||

| Frequency | DC or 47-63 Hz | ||

| Power consumption (typical, base meter) | 1.2W @ 120 Vac, 1.5W @ 240 Vac, 1.3W @ 10 Vdc, 1.4W @ 20 Vdc, 1.55W @ 30 Vdc, 1.8W @ 40 Vdc, 2.15W @ 48 Vdc | ||

| Power Isolation | 250V rms working, 2.3 kV rms per 1 min test | ||

| Serial Interface (one required) | |||

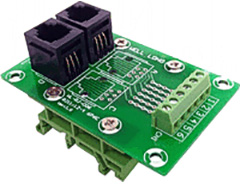

| Board selections | RS232, USB, RS485 (dual RJ11), RS485 (dual RJ45), | ||

| ASCII data rates | 300 to 9600 baud | ||

| Isolation | 250V rms working, 2.3 kV rms per 1 min test | ||

| Analog Output (optional) | |||

| Output levels | 4-20 mA, 0-20 mA, 0-10V, -10 to +10V | ||

| Current compliance | 2 mA at 10V ( > 5 kΩ load) | ||

| Voltage compliance | 12V at 20 mA (< 600Ω load) | ||

| Scaling | Zero and full scale adjustable from -99999 to +99999 | ||

| Resolution | 16 bits (0.0015% of full scale) | ||

| Isolation | 250V rms working, 2.3 kV rms per 1 min test | ||

| Relay Outputs (optional) | |||

| Dual magnetic relays | 2 Form C, 10A max, 440Vac or 125Vdc max, 2500VA or 300W | ||

| Quad magnetic relays | 4 Form A (NO), 10A max, 440Vac or 125Vdc max, 2500VA or 300W | ||

| Dual solid state relays | 2 Form A (NO), AC or DC, 0V - 400V, 120Ma, 35Ohms (max at On-State) | ||

| Quad solid state relays | 4 Form A (NO), AC or DC, 0V - 400V, 120Ma, 35Ohms (max at On-State) | ||

| Relay commons | Isolated commons for dual relays or each pair of quad relays | ||

| Relay isolation | 250V rms working, 2.3 kV rms per 1 minute test | ||

| Relay latching modes | Latching or non-latching | ||

| Relay active modes | Active on or off, active high or low | ||

| Hysteresis modes | QA passband mode, split hysteresis, span hysteresis | ||

| Environmental | |||

| Operating temperature | -40°C to 70°C (-40°F to 158°F) | ||

| Storage temperature. | -40°C to 85°C (-40°F to 185°F) | ||

| Relative humidity | 95% at 40°C, non-condensing | ||

| Protection | NEMA-4X (IP-65) when panel mounted | ||

| Mechanical | |||

| Enclosure | 1/8 DIN, high impact plastic, UL 94V-0, color: black | ||

| Mounting | 1/8 DIN panel cutout required: 3.622" x 1.772" (92 mm x 45 mm). | ||

| Dimensions | 4.68" x 2.45" x 5.64" (119 mm x 62 mm x 143 mm) (W x H x D) | ||

| Maximum panel thickness | 4.5 mm (0.18") | ||

| Tightening Torque - Connectors | Screw terminal connectors: 5 lb-in (0.56 Nm) | ||

| Tightening Torque - Pawls | Digital Panel Meter Case Pawls: 5 lb-in (0.56 Nm) | ||

| Weight of base meter | 210 g (7.4 oz) typical (DPM, counter, timer, 6-digit remote display) | ||

| Weight of option boards | 30 g (1.0 oz) typical per board (analog output, relay output, communications) | ||

| General | |||

| Programming Methods | Four front panel buttons or via Laurel's free Instrument Setup Software, which runs on a PC under MS Windows. | ||

| Security | Lockout options include using the front panel buttons, the free Instrument Setup Software, or a hardware jumper. | ||

| Warranty | 3 years parts & labor | ||

| Recalibration: All ranges are calibrated at the factory. Recalibration is recommended every 12 months. | |||

Free Instrument Setup Software for Series 2 Laureates

Free Downloadable Windows-based Instrument Setup (IS) software (Data Interface Board Required) for use with our programmable Digital Panel Meters, Scale Meters, Counters, Timers, Remote Displays, and Transmitters, are an easy method to set up Laureate 1/8 DIN digital panel meters, counters, timers, remote displays, and DIN-rail transmitters, as explained in the Instrument Setup Software Manual. Laureate 1/8 DIN instruments can also be set up from the front panel, as explained in their respective Owners Manuals. Instrument Setup software is of benefit whether or not the PC is connected to the instrument.

- When the PC is connected to the instrument, Instrument Setup software can retrieve the setup file from the instrument or open a default setup file or previously saved setup file from disk View Setup, then provides graphical user interface (GUI) screens with pull-down menus applicable to input, display, scaling, filtering, alarms, communications, analog output, and front panel lockouts. Fields that are not applicable to the instrument as configured are either left out or grayed out. Clicking on any item will bring up a detailed Help screen for that item. After editing, the setup file can be downloaded, uploaded to the instrument, or saved to a disk. The same setup file can then be downloaded into multiple instruments.

- When the PC is not connected to the instrument, the above GUI screens can be used to set up a virtual instrument. The setup file can then be saved to disk. Switching toView Menu then brings up a screen with the required front panel programming steps. This view can be printed out for use at the instrument site and to serve as a hard copy record.

Download Free Instrument Setup Software

Installation

Set User Account Control (UAC) of MS Windows to "Never notifiy me" so that Instrument Setup Software can create directories. The UAC change screen can be reached as follows:

- Under Windows 7, click on the Windows Start button in the lower left of the desktop and enter "UAC" in the search field.

- Under Windows 8, navigate to Control Panel, then to the "User Accounts and Family Safety" section, and click on "Change User Account Control Settings."

- Under Windows 10, click on the Windows Start button in the lower left of the desktop, then on "Settings", and enter "UAC" in the search field.

- Reboot your computer for the changed UAC setting to take effect.

RJ11-to-DB9 cable with rear view of DB9 connector to PC

RS232 cable, meter to PC, P/N CBL01

Laureate 1/8 DIN Laureate instruments must be equipped with a serial communications board and be connected to the computer via a serial communications cable. The connection can be via RS232, RS485, USB or Ethernet. Following setup, the serial communications board may be removed from the instrument if desired. The wiring of the RS232 cable is illustrated above with end views of the two connectors.

Laureate LT Series transmitters come standard with a 3-wire serial interface, which can be jumpered for RS232 or RS485.

Laureate LTE Series transmitters come standard with an Ethernet interface.

Meter Setup Screens

Click on any of the reduced screens below for a full-size screen view, then click on the Back button of your browser to return to this page. The screens examples below are for a fully-loaded Series 2 Digital Panel Meter (DPM), which is connected to the PC via RS232. If the meter is a Series 1 meter (pre-2007), this is sensed by the software, and somewhat different screens are brought up. Please see Series 1 setup screens.

Meter Setup Utilities

From the Main Menu, click on Readings if your PC is connected to the meter. A pull-down menu then offers three choices: List, Plot and Graph.

- List presents the latest readings in a 20-row by 10-column table. Press Pause at any time to freeze the display. This is one method to capture peak readings.

- Plot generates a plot of readings vs. time in seconds. It effectively turns the DPM-PC combination into a printing digital oscilloscope.

- Graph generates a histogram where the horizontal axis is the reading and the vertical axis is the number of occurrences of readings. The display continually resizes itself as the number of readings increases.

Laureate™ 1/8 DIN Case For Laureate Digital Panel Meters, Counters, Timers & Remote Displays

Key Features

- Meets 1/8 DIN Standard.

- Installs from front of panel.

- Short depth behind the panel: only 4" (102 mm) plus connectors.

- Understated 0.157" (4 mm) thick bezel.

- Meets NEMA 4X (IP-65) for high-pressure wawshdon when panel mounted.

- Screw clamps connectors meet VDE / IEC / UL / CSA safety standards.

- Rugged GE Lexan® housing material.

- Safety certified per EN 61010-1.

Dimensions

Maximum panel thickness: 4.5 mm (0.18")

Weight of base meter: 210 g (7.4 oz) typical (DPM, counter, timer, 6-digit remote display)

Weight of option boards: 30 g (1.0 oz) typical per board (analog output, relay output, communications)

Tightening Torque - Connectors: Screw terminal connectors: 5 lb-in (0.56 Nm)

Tightening Torque - Pawls: Digital Panel Meter Case Pawls: 5 lb-in (0.56 Nm)

Dimensioned CAD assembly drawings in EPRT, STEP, x_t. dwg, pdf file formats: Laureate-meter-case.zip (zipping prevents browser from opening CAD files as text files).

Panel Mounting

Slide the meter into a 45 x 92 mm 1/8 DIN panel cutout. Ensure that the provided gasket is in place between the front of the panel and the back of the meter bezel.

The meter is secured by two pawls, each held by a screw, as illustrated. Turning each screw counterclockwise extends the pawl outward from the case and behind the panel. Turning each screw clockwise further tightens it against the panel to secure the meter.

Slide the meter into a 45 x 92 mm 1/8 DIN panel cutout. Ensure that the provided gasket is in place between the front of the panel and the back of the meter bezel.

The meter is secured by two pawls, each held by a screw, as illustrated. Turning each screw counterclockwise extends the pawl outward from the case and behind the panel. Turning each screw clockwise further tightens it against the panel to secure the meter.

Turning each screw counterclockwise loosens the pawl and retracts it into its well. This position allows installed meter to be removed from their panel, or new meters to be installed in a panel. Do not remove the screws from their pawls. Doing so would cause the screw and pawl to fall off and likely get lost. Do not overtighten so as not to damage the plastic parts.

| Duty Cycle & Pulse Width Modulation (PWM) Modes | |

|---|---|

|

|

| Monitoring Laser OperationPM and Speed | |

|

The display of a Laureate counter can be augmented by up to three slave displays to show up to four parameters simultaneously : Items #1, #2, #3 and peak rate (if rate was one of the selected items). All four parameters can also be displayed at a remote location. |

IPC

Splashproof Cover

CBL01

RS232 Cable for Meters

CBL02

USB-to-RS232 Adapter Cable

CBL04

RS232 Cable for LT Transmitters

CBL05

USB Data Cable for Meters

CBL06

USB-to-RS485 Adapter Cable

CBL07

USB Programming & Data Cable

CBL08

RS485 Splitter Cable

BKBD

RS485 RJ11 Terminal Block Adapter

What are 1/8 DIN Digital Panel Meters for Serial Input 6-Digit & Remote Display?

Introduction

In industrial automation and instrumentation, precision and clarity in displaying measurements are crucial. The 1/8 DIN Digital Panel Meters Serial Input 6-Digit & Remote Display is a compact yet powerful device designed to meet these needs. This article will explain what this device is, its features, applications, and why it is essential in various industrial environments.

Understanding DIN Standards

Before diving into the specifics of 1/8 DIN Digital Panel Meters, it’s important to understand what "DIN" refers to. DIN stands for "Deutsches Institut für Normung," the German Institute for Standardization. DIN standards are widely used globally to ensure compatibility and consistency in mechanical and electrical components.

The "1/8" in 1/8 DIN refers to the size of the device. DIN sizes are standardized, and 1/8 DIN implies that the digital panel meter's front panel measures approximately 1.89 x 3.78 inches (48 x 96 mm). This compact size allows for easy integration into control panels and other equipment.

What are 1/8 DIN Serial Input 6-Digit Digital Panel Meters?

1/8 DIN Serial Input 6-Digit Digital Panel Meters are a digital device used for displaying numerical data. The "6-Digit" part indicates that it can display values up to six digits, offering precision in measurement. The "Serial Input" aspect means that these digital panel meters can receive data via serial communication protocols such as RS-232, RS-485, or Modbus. This makes it highly versatile, allowing it to be connected to various sensors, controllers, or other devices that output data serially.

Key Features

-

Compact Size: The 1/8 DIN form factor makes it ideal for installations where space is limited.

-

High Precision: With the capability to display up to six digits, these digital panel meters can show detailed and accurate readings.

-

Serial Communication: The ability to receive data through serial inputs allows integration with a wide range of devices, including PLCs (Programmable Logic Controllers), computers, and other automation equipment.

-

Customizable Display: Many of these digital panel meters offer configurable display options, such as adjustable brightness, color, and digit height, making it easier to read in various lighting conditions.

-

Remote Display: Some models offer a remote display feature, allowing the numerical data to be shown at a different location from the main device. This is particularly useful in large or complex installations.

Applications

-

Industrial Automation: These digital panel meters are commonly used in industrial settings to display parameters like temperature, pressure, voltage, current, or flow rates, received from sensors or controllers.

-

Process Monitoring: In manufacturing plants, these digital panel meters can be used to monitor and display critical process parameters, ensuring everything operates within specified limits.

-

Energy Management: The digital panel meters can be used in energy monitoring systems to display real-time data on power usage, helping to optimize energy consumption.

-

Laboratory Equipment: In scientific and research labs, these devices can be used to display precise measurements from experiments or processes.

-

Building Management Systems: The digital panel meters can be integrated into BMS (Building Management Systems) to display and monitor environmental parameters such as temperature and humidity.

Why Choose 1/8 DIN Serial Input 6-Digit Digital Panel Meters?

The choice of a 1/8 DIN Serial Input 6-Digit & Remote Display is driven by its balance of compact size, precision, and versatility. Its ability to integrate with a wide range of devices through serial communication and its customizable display make it a valuable tool in any environment where accurate data display is critical. Whether you’re managing a complex industrial process, monitoring energy usage, or conducting scientific research, this device provides the reliability and precision you need.

Conclusion

In summary, the 1/8 DIN Serial Input 6-Digit Panel Meter & Remote Display is a highly efficient and versatile tool that meets the demands of modern industrial and scientific applications. Its compact size, precision, and flexibility make it a preferred choice for professionals seeking reliable and accurate data display solutions.

Understanding the 1/8 DIN Serial Input 6-Digit Panel Meter & Remote Display

Introduction

The 1/8 DIN Serial Input 6-Digit Panel Meter & Remote Display is a versatile and precise instrument used in various industrial applications. DIN, short for "Deutsches Institut für Normung," refers to the German Institute for Standardization, which defines the size and dimensions of these digital panel meters, making them universally compatible. The "1/8 DIN" size means that the meter is one-eighth of the standard DIN size, which is 96 x 48 mm. This compact size makes it ideal for use in space-constrained environments while still providing clear and accurate readings.

Key Features

- 6-Digit Display: The 6-digit display offers high resolution, allowing for precise measurements to be shown.

- Serial Input: Serial communication capabilities make these digital panel meters suitable for integration into larger control systems. They can receive data from various sources such as sensors, transducers, or PLCs (Programmable Logic Controllers).

- Remote Display Capability: The ability to connect to a remote display ensures that readings can be monitored from a distance, which is particularly useful in large or hazardous industrial environments.

Applications of 1/8 DIN Serial Input 6-Digit Digital Panel Meters & Remote Displays

-

Industrial Process Monitoring

- Temperature Control: In industries such as food processing, chemicals, and pharmaceuticals, precise temperature monitoring is crucial. The digital panel meters can display real-time temperature data received from thermocouples or RTDs (Resistance Temperature Detectors).

- Pressure Measurement: In applications where pressure needs to be monitored, such as in HVAC systems or hydraulic machines, these digital panel meters can display the pressure data with high accuracy, ensuring safe and efficient operation.

-

Manufacturing Automation

- Production Line Monitoring: In automated production lines, these digital panel meters can be used to monitor various parameters such as speed, count, and position. Its serial communication allows it to interface with other control systems to ensure that the production process is running smoothly.

- Quality Control: These digital panel meters can be used in quality control applications to measure dimensions, weight, or other critical parameters. The high precision of the 6-digit display ensures that even the smallest deviations are detected.

-

Energy Management

- Power Monitoring: In energy management systems, the digital panel meters can be used to monitor voltage, current, or power consumption. This data is critical for optimizing energy use and reducing costs in commercial and industrial buildings.

- Renewable Energy Systems: In renewable energy applications, such as solar or wind power, the digital panel meters can be used to monitor the performance of inverters, batteries, or other components, ensuring that the system is operating at peak efficiency.

-

Remote Monitoring and Control

- Hazardous Environments: In hazardous environments, such as oil refineries or chemical plants, it may be unsafe for personnel to be physically present to monitor equipment. The remote display capability allows for safe monitoring from a control room or other secure location.

- Large Facilities: In large industrial facilities, where equipment may be spread out over a wide area, the remote display feature allows for centralized monitoring, reducing the need for personnel to move around the facility to check equipment.

Conclusion

The 1/8 DIN Serial Input 6-Digit Panel Meters & Remote Display is an essential tool in modern industrial and commercial applications. Its compact size, high precision, and ability to interface with other systems make it ideal for a wide range of uses, from process monitoring to energy management. Whether used in a manufacturing plant, an energy management system, or a hazardous industrial environment, these digital panel meters provides reliable and accurate data to ensure efficient and safe operations.

Less Information.